1. Customer and Sector

MITA Cooling Technologies’ client is one of Poland’s largest poultry processing companies, exporting throughout Europe and the world. It still follows the entire production process “from field to table,” being able to rely on its own farms.

Every company in the food & beverage business has its own refrigeration needs, and this one is no exception. For this reason, the company has been followed by a number of interlocutors attentive to listen to specific and detailed requests: especially the EETS agency of engineer Bartosz Jagieła, with the support of MITA Cooling Technologies staff.

2. Customer requests

The revamping of the Polish company’s facilities involved the central plant. Autoclaves are used to sterilize the finished product, and in the process, the coolant used (polypropylene glycol) had to be raised from 60° to 20° C temperature.

The autoclaves had to be kept operational at maximum efficiency. A request from the customer was to still have an eye on resource optimization.

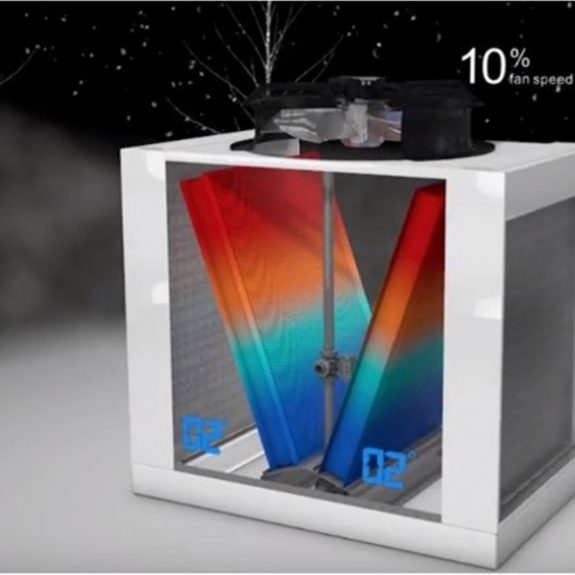

3. The solution: adiabatic cooler PAD-V

The needs of the poultry processing company were married with the selection of a PAD-V 2-6 adiabatic cooler. This system is also sometimes called an adiabatic dry cooler precisely because, to achieve efficiency and resource optimization, it uses a dual mode of operation depending on the different time of year:

- dry during cold periods;

- in adiabatic mode, thus with water pre-cooling, during the hot season of the year.

The switch from one mode to the other is manually programmable, according to the actual needs of the period, by means of a user-friendly PLC computer. The selected chiller works in dry mode below 18° C outdoor temperature, wet up to 27°, wet with chiller contribution up to 35°.

The system, which is fully parameterizable, also automatically adjusts the rotation speed of the two fans: this is according to the heat load, outdoor temperatures, and water and energy consumption targets.

4. Critical success factors

By the client company’s own admission, the offer of MITA Cooling Technologies and EETS stood out for the clarity of the technical specification presented and the reliability of the proposed solution.

On the other hand, the very low resource utilization of the cooling process with PAD-V, embedded in the plant, are easily calculated:

- just over 10,000 kW per year of energy for the motor-fan units,

- only 81 m3 of water per year for adiabatic operation.

The temperature difference between the incoming and outgoing liquid is 40° C throughout the year: efficiency and operational continuity.

Ask for information