Ressources

Des technologies de refroidissement aux rayons X pour vousUne sélection d'articles techniques, des normes de qualité définies par des organismes internationaux, une théorie des technologies de refroidissement.

FAQ

Quelle est la différence entre le refroidissement par évaporation et le refroidissement adiabatique ? Dans quels cas faut-il choisir une tour de refroidissement à circuit ouvert ou fermé ? Qu'est-ce que le sous-refroidissement ? Une section mise à jour en permanence pour répondre aux questions les plus fréquemment posées dans les secteurs industriel et civil.

Aller à la pageThéorie des technologies de refroidissement

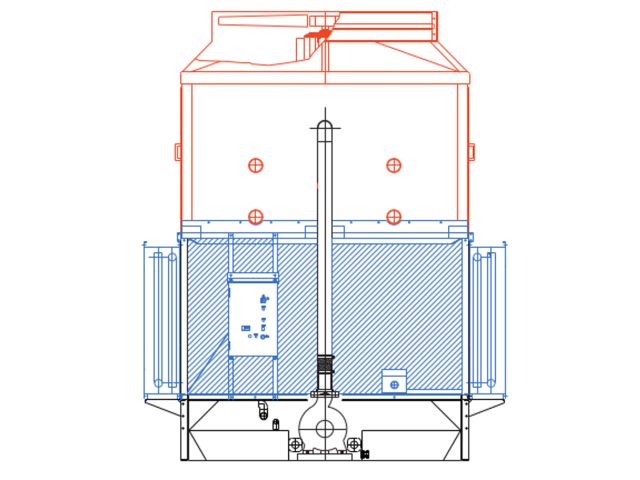

Comment fonctionnent les tours de refroidissement à circuit ouvert et fermé, les condenseurs évaporatifs et les systèmes adiabatiques : un guide rapide pour comprendre les technologies de refroidissement.

Aller à la page

Meilleures pratiques

Les directives pour garantir l'efficacité et la sécurité des vos technologies de refroissement sont recommandées par des organismes internationaux: Eurovent, Assoclima (Confindustria) et Cooling Technology Institute. La présence institutionnelle aux tables réglementaires italiennes et européennes est l'un de nos objectifs.

Aller à la pageGlossaire

Tout sur les technologies de refroidissement. Solutions techniques, composants et accessoires, notions physiques. La terminologie de la théorie évaporative et adiabatique de A à Z.

Aller à la page

Articles techniques

La bonne section si vous souhaitez en savoir plus sur les technologies de refroidissement: tours de refroidissement, refroidisseurs adiabatiques, aéroréfrigérants, refroidisseurs pour procédés industriels. Et comment gérer chaque plante.

Aller à la pageRefroidissement industriel: ce qu’il faut savoir

Comparaison des technologies de refroidissement : évaporatif, adiabatique, air, mécanique. Conception et construction de systèmes de refroidissement industriels. Secteurs, études de cas, solutions de refroidissement sur le marché.

Aller à la pageTour de refroidissement : fonctionnement et utilisation

Aller à la pageRefroidissement Adiabatique Industriel: ce qu’il faut savoir

Refroidissement adiabatique et refroidisseurs adiabatiques en détail : description, fonctionnement, applications. Refroidissement adiabatique par rapport au refroidissement par évaporation.

Aller à la pageL’efficacité et la sécurité des refroidisseurs vont de pair avec un entretien correct.

Nous suivons les directives officielles des organismes internationaux tout en vous conseillant sur la meilleure solution pour une gestion correcte de l’installation et pour le traitement de l’eau dans le cas des tours de refroidissement, notamment Eurovent, Assoclima (Confindustria – Association italienne des industries) et le Cooling Technology Institute. Assurer une présence institutionnelle aux tables rondes réglementaires italiennes et européennes est l’un de nos objectifs.

Documents disponibles sur la page Ressources de notre site web.

Ressources

Bonnes Pratiques

Ce qu'il faut savoir

Découvrez tous les termes techniquesArticles techniques

Newsletter

Abonnez-vous à la newsletter MITA et restez au courant des solutions techniques pour le refroidissement industriel et civil et découvrez notre offre.