Fiberglass cooling towers offer an efficient and highly durable solution for managing industrial heat, thanks to the unique properties of the material.

Compared to galvanized steel or concrete structures, they provide an excellent balance of thermal performance, resistance, and operating costs.

- Resistance and durability. Fiberglass is naturally resistant to corrosion and chemical agents—an essential advantage in industrial or coastal environments where steel tends to deteriorate quickly. It is also unaffected by microorganisms and maintains its properties even under extreme weather conditions or when exposed to aggressive water.

- Reduced maintenance and long service life. Fiberglass cooling towers do not rust or rot, requiring minimal maintenance and offering an average service life that can exceed 25 years. The smooth surface of the material limits scaling and makes cleaning easier, preserving heat-exchange efficiency over time.

- Efficiency and flexibility. Thanks to its light weight and versatility, fiberglass makes cooling towers easy to install—even on rooftops or structures with limited load capacity. The material’s insulating properties also help improve overall thermal performance by reducing heat losses.

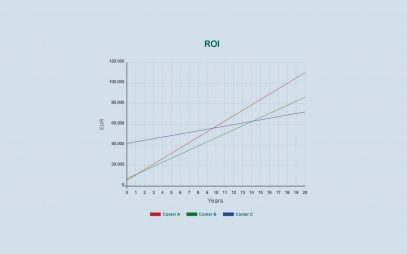

In summary, fiberglass cooling towers combine durability, efficiency, and operational sustainability, delivering a positive economic return throughout their lifecycle.

Selection and resource-optimization software now makes it possible to simulate, already during the design phase, the balance between energy, water, and sizing, allowing the best-performing and most sustainable solution to be identified for each industrial context.