Installation Context: engine test benches and test rooms for mechanical industry, compressors, mechanical production processes.

Cooling Technologies for the Mechanical Industry

The mechanical industry includes the most diverse sectors, in addition to metal and plastic processing: compressors and test benches are significant examples. Required temperature differences and water quality vary greatly depending on the industry: evaporative cooling towers can be used, preferably open-circuit ones (with exchange packs for dirty or clean water depending on the context) and adiabatic coolers for consumption optimize.

Requirements: low resource use, long life, low noise, highly variable output temperatures.

Overview of Cooling Technologies: remote control systems, integrated management systems, open circuit cooling towers.

Cooling technologies for the mechanical industry: two examples

Here are two examples of applications of cooling technologies for the mechanical industry: compressors and engine test benches.

- In air compression systems, tower water is used to dissipate the heat produced by the compressor, as well as to cool the air that heats up due to the compression.

- Regarding motor and brake test benches, industrial coolers are used to dissipate the heat produced by the motor and the brake during the relative test.

MITA Cooling Systems for the Mechanical Industry

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

MITA Systems Cooling Stations

Complete solutions specifically studied and designed for a more efficient and automatic management of evaporative cooling towers and coolers.

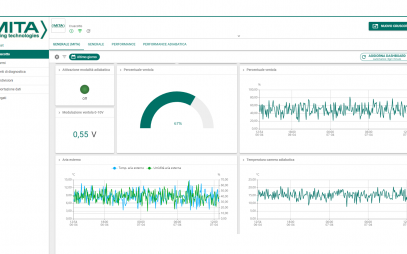

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA Projects for the Mechanical Industry

Closed-Cooling Towers for the Rotor Dynamics Lab (University of Pisa)

MITA Cooling Technologies and technology research in academia: in 2015, we participated in the tender for the cooling system of the 2 engine test benches attached to the Rotordinamica Laboratory of the University of Pisa.

Learn MoreClosed-Circuit Cooling Towers for Engine Test Bench

MITA built the cooling system for the electronically controlled hydraulic test bench at the Experimental Institute for Agricultural Mechanization (ISMA) in Treviglio: an MCC C series closed-loop evaporative tower. Among the benefits brought by the plant are reduced operating costs and water use.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.