Industrial Process Cooling: What to Know

Comparison of cooling technologies: evaporative, adiabatic, air, mechanical. Design and construction of industrial cooling systems. Sectors, case studies, cooling solutions on the market.

Industrial Cooling Systems: At a Glance

Evaporative Cooling Systems

Do you want performance and efficiency for your industrial cooling system? Then the cooling towers and evaporative condensers ensure both in an extraordinarily simple way. Innovative technical measures reduce water consumption and noise levels.

Adiabatic Cooling Systems

Extraordinary water and energy savings, optimized performance: adiabatic coolers and condensers are increasingly appreciated by engineers and production managers who seek the right balance between the advantages of the dry and evaporative systems.

Dry Cooling or Air Cooling

Use ease, zero water consumption, the ideal solution for medium-high process fluid temperatures.

Chillers for Industrial Processes

Fluid temperature far below ambient temperature: when this is necessary, mechanical cooling allowed by a chiller for industrial processes must be used.

Cooling Plant Construction: What to Know

Industrial Plant Cooling: 12 + 1 Things to Consider before Looking for a Manufacturer

Is this the first time you have to deal with the cooling of your industrial plant? Or maybe do you wish to see a complete reference framework to carry out this task for your company? These guidelines will help you choose the best cooling technology for your plant's specific project needs.

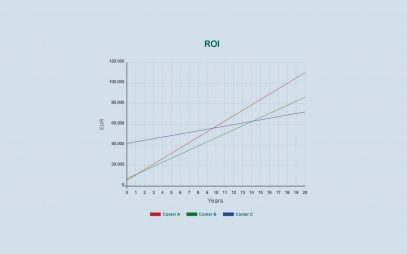

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Comparison between Cooling Tower and Adiabatic Cooler

Comparison of cooling tower (or evaporative tower) and adiabatic cooler: water and energy use, performance.

Theory of Cooling Technologies

How open and closed circuit cooling towers, evaporative condensers and adiabatic systems work: a quick guide to the knowledge of cooling technologies.

Cooling & Refrigeration Glossary

All about cooling technologies. Technical solutions, components and accessories, physical notions: the terminology of evaporative and adiabatic theory with terms and definitions from A to Z.

European Green Deal and Cooling

The European Commission has set itself the goal of achieving climate parity in 2050. The development of the economy must be sustainable, just think that over 75% of EU28 greenhouse gas emissions are attributable to energy production and the 20% is attributable to the industrial sector.

Cooling System Design: the Different Needs

Design of a New Plant

Let's talk about your project needs: this is where we start to select the cooling technology that best suits your system. Then we will design a truly tailor-made solution, with the required customizations, calculating the optimization of your consumption with advanced tools.

Replacement of a Cooling System

Cooling systems which are corroded or that no longer support initial performance: both can be replaced with the most diverse market solutions. As a premise, a serious pre-analysis must be carried out on the plant requirements.

Cooling System Upgrade

A few, necessary steps are enough. An industrial cooler must support all kinds of new requirement in the industrial or civil process: higher temperature ranges, water and energy optimization, new sound levels.

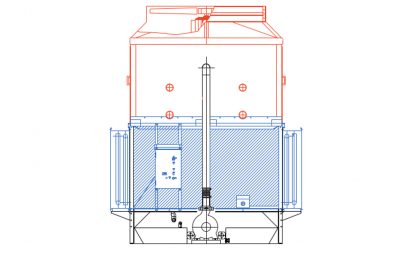

Revamping and Retrofitting of Cooling Systems

Refurbishment of large towers or targeted anti-corrosion interventions, change of internal components and retrofitting with subcooling: it is not always necessary to replace a cooler or an industrial chiller. It is often more useful to give it a plus.

Optimized Industrial Coolers for Different Sectors

Cooling Systems in Food Industry

In the food industry, cooling systems play a crucial role in preserving finished product quality and ensuring business continuity. MITA Cooling Technologies’ cooling technologies, such as closed-loop evaporative towers and adiabatic dry coolers, ensure precise and consistent temperatures for delicate food processes without compromising the safety and purity of process fluids.

Cooling systems for metalworking

Metal processing requires reliable, high-efficiency cooling systems to maintain stable temperatures during processes such as casting, rolling, and stamping. MITA Cooling Technologies offers advanced industrial cooling solutions: evaporative towers, dry coolers, adiabatic systems supported by parameter control panels. Reliability, precision, resource optimization: the cooling systems the metal processing industry needs.

Cooling Systems for Paper Mills and Pulp

Le cartiere richiedono un raffreddamento efficiente per gestire le elevate portate di acque spesso sporche, contaminate da residui di cellulosa. MITA Cooling Technologies offre soluzioni di raffreddamento in vetroresina non-corrodibile, compatte o modulari e containerizzabili, ideali per ottimizzare i costi e agevolare il trasporto a lunga distanza. Torri di raffreddamento a circuito aperto e chiuso garantiscono performance costanti, facilità di manutenzione e resistenza all'intasamento.

Cooling Systems for Industrial Wastewater

Multiple industries have a cross-sectoral need to cool wastewater from their production processes: these include textile, paper, and food companies. In this area, it is best to use evaporative towers with anti-clogging exchange packs for dirty industrial water. MITA offers efficient and sustainable cooling solutions, with evaporative towers designed to ensure long life even with dirty water and high flows.

Focus: cooling technologies for datacenters

With the increase in computing resources required, whether by massive use of the Internet or new applications of artificial intelligence, datacenters are becoming increasingly large and energy intensive. Cooling technologies must therefore reconcile performance with water and energy savings: from efficient cooling towers to structurally simple dry coolers to adiabatic dry coolers and chillers, the focus is always on the needs of the individual project.

Industrial Cooling Plants: Case Studies

- Industrial Wastewater

Cooling Revamp of a Wastewater Treatment Plant

In 2019, MITA Cooling Technologies sold 4 PME-E open circuit cooling towers to a Swedish paper mill. The "Super Silent" version of the PME-E makes it possible to meet the customer's extraordinary low sound level requirements.

Learn More

- Food & Beverage Industry

Cooling Efficiency for a Food Company in Poland

MITA Cooling Technologies scores, together with the agency EETS, a new achievement for the food industry: a poultry products company chose the PAD-V adiabatic cooler for a section of its production processes.

Learn More

- Food & Beverage Industry

Cooling Technologies for a High-Quality Food Process

More than a hundred years ago it was an apple orchard: now it is one of the most important food industries in Sweden. This is the company to which MITA Cooling Technologies and CAMPreq have provided solutions-as manufacturer and process cooling consultant, respectively.

Learn More

Cooling Solutions in the Market

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

PMM Modular Cooling Tower

This is a series of large industrial cooling towers for power generation, steel and aluminium processing, cogeneration and other large production sites. Efficiency, high performance, reduced installation and transport costs are granted.

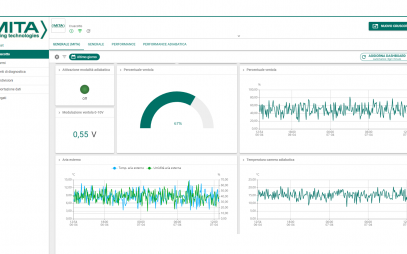

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.