Cooling Tower Protection

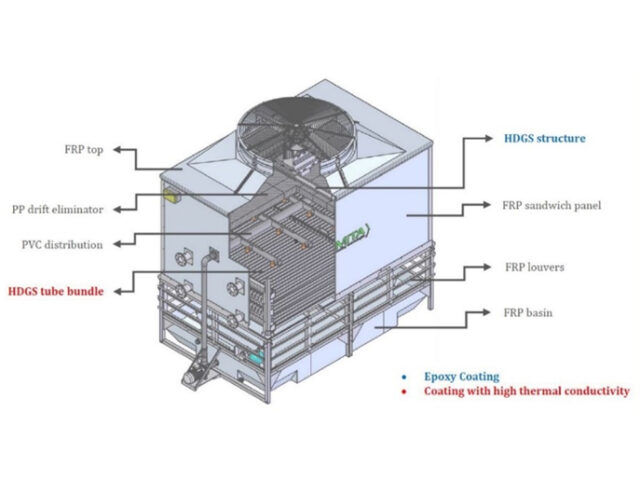

The cooling towers of MITA Cooling Technologies are made of long-lasting materials: fibreglass, PP and PVC, hot-dip galvanized steel. Furthermore, the customer can choose C-Protection Coating: an additional protection of hot-dip galvanized steel parts.

Maximum corrosion protection

Cooling towers are devices installed outdoors and always in contact with water. The ones proposed by MITA Cooling Technologies are made you materials granting a very long product life over time. Here below the list of materials:

- Fiberglass: composite material. It allows optimal corrosion resistance characteristics for any application. It is used for water collection basins, external casing and fan diffusers.

- PP and PVC: plastic materials, for heat exchange fillpacks, nozzles and water distribution system.

- Hot-dip galvanized steel: it is used for the perimeter frame and structure and the cooling coils, after an hot galvanizing process (≥ 80μm, following all processes).

Steel components can be offered in a “stainless steel” version (AISI 304, AISI 316), or covered with a special protective layer, “C-Protection Coating”, added to the Hot Dipped Galvanized Zinc layer.

These options are useful for those installation contexts where it’s present an aggressive environment or water; or again, where you want to increase the resistance of the component to the external environment, with a limited additional investment (with the protective coating).

Advantages of C-Protection Coating

- Additional protection to parts made of hot-dip galvanized steel.

- Cost-effective alternative to stainless steel.

- Water saving, higher concentration factor.

- Designed around water quality, environmental conditions and expected product life.

- Low maintenance.

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesTools to help you choose

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.