Adiabatic Cooling System: How it Works, Examples & Solutions

Adiabatic cooling and adiabatic coolers in detail: description, function, applications. Adiabatic cooling compared to evaporative cooling.

Adiabatic Cooling System: How it Works

Adiabatic Cooling Systems

Extraordinary water and energy savings, optimized performance: adiabatic coolers and condensers are increasingly appreciated by engineers and production managers who seek the right balance between the advantages of the dry and evaporative systems.

Comparison between Cooling Tower and Adiabatic Cooler

Comparison of cooling tower (or evaporative tower) and adiabatic cooler: water and energy use, performance.

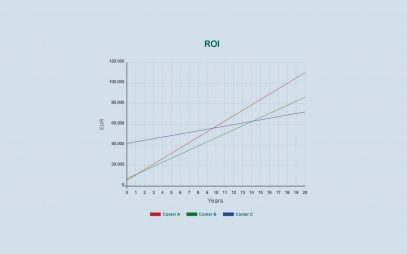

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Adiabatic Cooling Application: Examples

Cooling Systems in Food Industry

In the food industry, cooling systems play a crucial role in preserving finished product quality and ensuring business continuity. MITA Cooling Technologies’ cooling technologies, such as closed-loop evaporative towers and adiabatic dry coolers, ensure precise and consistent temperatures for delicate food processes without compromising the safety and purity of process fluids.

Cooling Systems for Plastic and Rubber Processing

Plastic and rubber processing requires specific cooling processes to ensure high productivity, finished product quality and temperature control during molding, extrusion and mixing. MITA Cooling Technologies offers advanced solutions-from chillers to adiabatic cooling systems-that optimize the cooling of molds, hydraulic components and oils, ensuring reliability and energy savings.

Cooling Technologies for the Cold Chain in Logistics

Foodstuff storage at temperatures below zero can be implemented through different types of natural or non-natural refrigerants: evaporative or adiabatic condensers can be indicated, depending on whether the company is focused on performance or resource use optimization. Low noise solutions are often appreciated.

Focus: cooling technologies for datacenters

With the increase in computing resources required, whether by massive use of the Internet or new applications of artificial intelligence, datacenters are becoming increasingly large and energy intensive. Cooling technologies must therefore reconcile performance with water and energy savings: from efficient cooling towers to structurally simple dry coolers to adiabatic dry coolers and chillers, the focus is always on the needs of the individual project.

Plants with Adiabatic Cooling Systems

- Plastic and Rubber Processing

Cooler Replacement for a Manufacturer of Porcelain Products in the Netherlands

Significant water savings and a wide range of available solutions-these two factors were key for a Dutch manufacturing company replacing its cooling systems. Two adiabatic dry coolers from MITA Cooling Technologies.

Learn More

- Plastic and Rubber Processing

Extraordinary water savings for the plastics industry with the MITA adiabatic system

A plastics processing company in the province of Lecco has chosen the PAD-V cooler for the cooling circuit of its production plant: the eco-sustainable system that cuts water and energy bills.

Learn More

PAD Adiabatic Coolers for Ansaldo Energia (Utilities)

One of the most advanced poles for the study of power grids in Europe, in Sardinia, also bears the signature of MITA Cooling Technologies: this is thanks to 13 adiabatic coolers supplied to Ansaldo, among the main implementers of the work.

Learn More

Adiabatic Cooling Systems: Solutions on the Market

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

PAD-XL R Adiabatic Condenser

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

Alchemist Adiabatic Sucooler

Performance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.