Installation Context: food storage (dairy products, fruit and vegetables, meat and cold cuts).

Cooling Technologies for the Cold Chain in Logistics

Foodstuff storage at temperatures below zero can be implemented through different types of natural or non-natural refrigerants: evaporative or adiabatic condensers can be indicated, depending on whether the company is focused on performance or resource use optimization. Low noise solutions are often appreciated.

Requirements: low resource use, continuity of operation, different refrigerants to condense/cool

efficiency, low noise.

Overview of Cooling Technologies: adiabatic condensers, evaporative condensers, remote control systems.

Cooling technologies for the cold chain in logistics: at a glance

The evaporative cooling tower (or other technology) serves to cool the water coming from the condensers, as in all refrigeration units.

The thermal difference considered is classically of 5 ° C, while the calculation of the thermal potential is carried out on the basis of the total cooling capacity of the compressors to be cooled: it is normally expressed in kW or in HP (1 HP = 1 KW x 1 , 36).

Ask for InformationMITA Cooling Systems for Cold Chain

MCE Evaporative Condenser

Compact, efficient and easily accessible: MCE evaporative condenser ensures refrigeration operators all the operating standards of its own technology class. The typical MITA evaporative coolers’ durability over time is a plus. MCE-EC version available with electronically controlled fans.

PAD-XL R Adiabatic Condenser

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

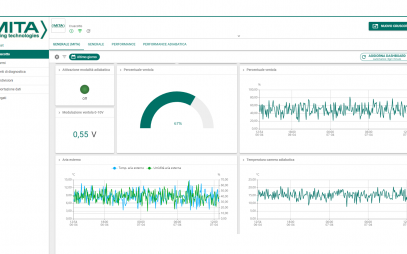

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Your Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.