Tailor-made design for each application

Different plants and sectors have different needsComplete range of coolers and chillers, dozens of variants for each type, solutions for each application and important customizations: MITA's design is truly tailor-made.

From industry to HVAC, via cogeneration

Different plants and sectors have different requirements. Some examples of customer requirements:

- high performance and high efficiency in industrial processes,

- attention to sound levels in civil air conditioning,

- business continuity, in order not to lose focus on activities related to core

Each type of MITA cooling system and chiller (evaporative, adiabatic, dry, mechanical) has different strengths to meet these requirements. For each type, there are dozens of size and power variants… and non-standard solutions that can be designed for the individual system.

Tell Us Your Needs

Advantages

- Wide range of evaporative, adiabatic, dry and mechanical coolers.

- Fully customised products, even extreme customisation.

- Solutions to the needs of each application: resistance to high and low temperatures (industrial cooling), sound level control (HVAC), etc.

- Possibility of extending our consultancy to cover all aspects of cooler management with MITA Systems.

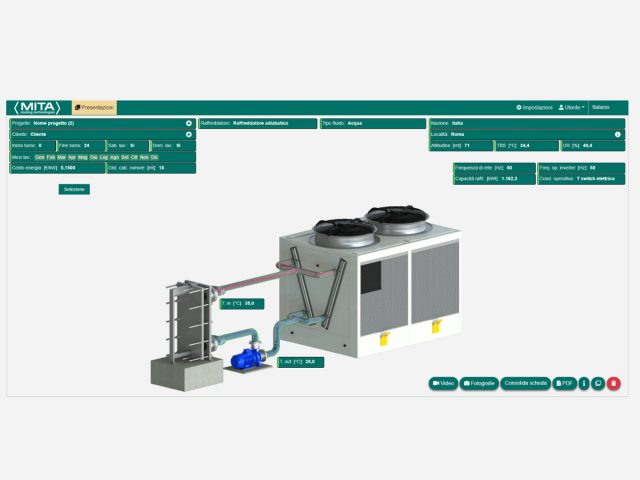

Co-designing a cooling system

At the design stage, all relevant information on the system is gathered together with the customer, including the support of advanced software tools: the design of the best cooling technology is therefore to all intents and purposes a tailor-made production of the technical department, which continues to work closely with the customer.

In addition to size and power variants, extensive customisation is possible with regard to accessories, electrical and hydraulic connections, internal machine accessibility, remote monitoring, etc.

Book Virtual AdviceAdvantages

- Wide range of evaporative, adiabatic, dry, mechanical coolers.

- Totally customized products, even extreme customizations.

- Solutions to the needs of each application: high and low temperature resistance (industrial cooling), sound level control (HVAC), etc.

- Possibility to expand our consulting also on everything related to cooler management with MITA Systems.

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesTools to help you choose

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.