Applications

Find your sector, tell us your needsWhich is your industry and what are your cooling needs? We have served the needs of engineering firms, plant installers and end users since 1960, installing more than 30,000 cooling towers and other cooling systems worldwide.

Industrial Plants

Food Industry

Cooling technologies for food industry must help preserve the quality of the finished product (and of the process liquid): this is true even more than in other industries. Closed circuit cooling towers and “hybrid towers” can make their contribution.

Metalworking

Foundries, steel mills, aluminum production lines: the plant managers of these industries require operational continuity, significant thermal jumps in cooling and cost containment for management and maintenance. Remote management platforms are an ally.

Chemical and Pharmaceutical Sector

We are talking about systems of very different sizes: as industrial fluid temperatures change the cooler must be sized accordingly. The operational continuity is fundamental, while the good life of the cooler is particularly appreciated (also thanks to non-corrodible solutions). Noise is not a problem, thanks to sound-absorbing technical solutions.

Textile Industry and Tanneries

The demands of these industries are linked to the most variable temperature changes, depending on the single production process. An example is the drying of leather in tanneries, carried out thanks to vacuum pumps: the liquid ring of these tools is cooled by a cooling tower. Usually, dirty water is treated: for this very reason, open cooling towers with wide-passage exchange packs are suggested. The durability of the solutions adopted is appreciated: fiberglass is a plus.

Paper Mills

In this sector, high water flow rates best fit large industrial cooling towers. It is often required to transport the units over great distances: for this reason, it is advantageous to rely on modular and / or “container” solutions, which also reduce management and installation costs.

Plastic and Rubber Processing

The plastics industry has gradually become attentive to operating resource use optimization and environmental sustainability: this is why adiabatic cooling systems seem ideal. Sometimes output temperatures below zero are required: in these cases we go to ad hoc chillers for industrial processes.

Industrial Wastewater

The different phases of the industrial water treatment process require defined cooling temperatures in accordance with regulations. In this sector, it is preferable to use cooling towers with anti-clogging fill packs for industrial contaminated water.

Mechanical Industry

The mechanical industry includes the most diverse sectors, in addition to metal and plastic processing: compressors and test benches are significant examples. Required temperature differences and water quality vary greatly depending on the industry: evaporative cooling towers can be used, preferably open-circuit ones (with exchange packs for dirty or clean water depending on the context) and adiabatic coolers for consumption optimize.

Oil & Gas

These industries are characterized by very high water flow rates. Modular industrial cooling towers, easily transportable over long distances despite their large size, are often suggested together with large concrete field-erected cooling towers.

HVAC

Offices

Low noise levels to ease daily life: this is the “must” of the cooling circuits attached to the air conditioning systems in the offices. Configurations suitable for restricted or peculiar spaces are also often required: the ideal are open circuit cooling towers with sound-absorbing technologies, possibly equipped with versatile centrifugal fans.

Healthcare Facilities

Hospital engineers pay attention to two fundamental needs: low noise level and simple maintenance to always keep equipment safe and efficient. Cooling technologies can meet these needs: evaporative and adiabatic coolers with sound-absorbing solutions, preferably with large accesses for internal inspections. The non-corrodible fiberglass can be a plus for useful machinery lifecycle extension.

Shopping Centers

The air conditioning systems in shopping centers must ensure low noise levels: the same goes for the attached coolers. Therefore, the engineering firms and plant installers are concerned with installing cooling solutions with sound-absorbing technologies, mostly evaporative. A further plus is the need to place the machine in confined spaces.

Tertiary Sector

Cinemas, theaters, buildings for public entertainment have the same needs as offices: the cooling units, attached to the air conditioning systems, must be silent and adapt to small spaces: also in this case, open-circuit cooling towers with sound-absorbing technologies are ideal. Centrifugal fans ensure space adaption, while non-corroding fibreglass extends product lifecycle.

Snowmaking Plants

Cogeneration and Trigeneration

Industrial Refrigeration

Cold Chain

Foodstuff storage at temperatures below zero can be implemented through different types of natural or non-natural refrigerants: evaporative or adiabatic condensers can be indicated, depending on whether the company is focused on performance or resource use optimization. Low noise solutions are often appreciated.

Refrigeration in the Food Sector

Refrigeration in the food sector is linked to production lines in food & beverage: the optimization of efficiency and resources (water and energy) are the most requested needs by customers. Evaporative and adiabatic condensers must be able to manage different refrigerant gases based on project requirements.

Commercial Refrigeneration

What is your industry and what are your cooling needs? We have been listening to the needs of engineering firms, installers and end users since 1960, installing more than 30,000 coolers in the world.

- Industrial cooling

- HVAC

- Industrial refrigeration

- Commercial refrigeration

- Artificial snowmaking

- Cogeneration and Trigeneration

Do you wish to have free advice?

Contact Us NowMITA Cooling Solutions

Industrial Dry Coolers

Ease of installation and use, remote control and zero water use. Industrial dry coolers are the right solution for cooling fluids requiring medium-high output process temperatures.

Industrial Chillers

Output temperatures down to -20 ° and remote control as a standard: the industrial chillers proposed by MITA are suitable for all the industrial processes.

MDC-F Table-Type Dry Cooler

No use of water, extreme simplicity of operation: these are the advantages of dry coolers in general and, in particular, of the MDC series with table coil configuration. MDC-F is an excellent solution for medium to high outlet fluid temperatures.

MDC-V V-Type Dry Cooler

Ease of installation, operation and maintenance–serving even large systems: this is the MDC-V V-shaped dry cooler. The peculiar design of the coils allows a larger heat exchange surface area than table-top dry cooler systems. All in an easily scalable solution.

PAD-XL W Adiabatic Cooler

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Suitable for both industrial and HVAC fields of application.

PAD-XS Adiabatic Cooler

Resource optimization of adiabatic cooling, for low flow rates and thermal capacities (20-50 kW), a more efficient alternative than a simple dry cooler. PAD-XS has a compact design with small footprint and low noise: an excellent solution for process cooling and small HVAC systems.

MCE Evaporative Condenser

Compact, efficient and easily accessible: MCE evaporative condenser ensures refrigeration operators all the operating standards of its own technology class. The typical MITA evaporative coolers’ durability over time is a plus. MCE-EC version available with electronically controlled fans.

Spare Parts

Keep your cooling system efficient and safe by replacing its obsolete components. The result? It will look like a newly installed technology.

PMS Evaporative Open-Circuit Cooling Tower

It is a cooling tower for industries of any type and for any water quality: very compact, self-supporting, light and long-lasting non-corrodible fiberglass structure.

PAD-XL R Adiabatic Condenser

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

PMM Modular Cooling Tower

This is a series of large industrial cooling towers for power generation, steel and aluminium processing, cogeneration and other large production sites. Efficiency, high performance, reduced installation and transport costs are granted.

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PU Industrial Cooling Tower

The PU series field-erected industrial cooling tower can serve very large plants: especially oil & gas, chemical and power generation. Available for all industrial water. Different materials are supplied according to project needs: concrete, steel, fiberglass and pultruded.

MCT Open-Circuit Evaporative Cooling Tower

Compact design and reduced dimensions: a range of evaporative cooling towers with centrifugal fans for special space configurations. MCT-EC version available with electronically controlled fans.

MCC Closed-Circuit Evaporative Cooling Tower

Some industries need to keep the chemical-physical characteristics of the process fluids unchanged: in these cases, MCC closed-circuit evaporative cooling tower joins the game. Possibility to work in free-cooling mode. MCC-EC version available with electronically controlled fans.

MCC-T Modular Closed-Circuit Evaporative Cooling Tower

MCC-T closed circuit evaporative tower allows to keep process fluids unaltered even in large plants. Some examples of applications: oil & gas, food industries, large paper mills. Easy transport of modules over long distances with reduced costs.

Alchemist Subcooler

Performance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

MITA Systems Cooling Stations

Complete solutions specifically studied and designed for a more efficient and automatic management of evaporative cooling towers and coolers.

Salinity Dosing and Control Stations

Cooling tower water has to be properly managed to keep the cooler always safe and efficient. Automatic solutions should be preferred. Systems for conditioning product dosing and salinity control: the heart and soul of cooling tower water treatment.

MITA Control System

MITA Control System allows programming and modulating cooler’s performances during its operations in a very simple way. Electricity use optimization is granted.

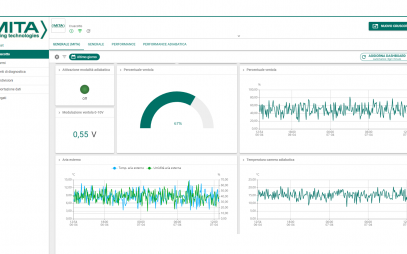

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Reinforced Concrete Tanks

A solution to properly (and separately) manage the hot and cold water of the evaporative system. Valves, solenoid valves, taps and fittings are supplied together with the concrete tanks.

Your Plant Needs

Tools to help you choose

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.