Examples of processes: tomato concentration, milk processing, cooling for ice cream parlors.

Cooling Systems in Food Industry

In the food industry, cooling systems play a crucial role in preserving finished product quality and ensuring business continuity. MITA Cooling Technologies’ cooling technologies, such as closed-loop evaporative towers and adiabatic dry coolers, ensure precise and consistent temperatures for delicate food processes without compromising the safety and purity of process fluids.

Typical needs: temperature control, fluid safety, energy efficiency.

Technologies offered: MCC closed evaporative towers, PAD-XL W adiabatic dry coolers, MITA IOTIoT platform for remote management.

Typical needs of the food industry

The food industry often requires cooling systems that guarantee a number of conditions.

- Finished product quality: maintaining optimal temperatures is critical to avoid alterations in food texture and taste.

- Safety and purity of fluids: contamination in production processes must be eliminated, especially when using process fluid.

- Continuity of operation: food production needs facilities that work without interruption to meet strict efficiency standards.

- Flexibility in temperatures: adaptation to specific needs, such as cooling liquids or solids at different stages of the process.

MITA Cooling Technologies' solutions for the food industry

MITA Cooling Technologies offers a range of ideal solutions to meet the cooling needs of the food industry.

- MCC closed cooling towers: perfect for avoiding process fluid contamination, they are ideal for productions requiring maximum hygiene.

- PME-E open cooling towers: versatile and highly efficient solution. Fiberglass as a construction material ensures durability (and continued operation) of such evaporative cooling systems.

- PAD-XL W adiabatic dry coolers: energy efficiency and low water use, ideal for sensitive sectors such as dairy.

- MDC-F and MDC-V dry coolers: specifically for cooling in total absence of water.

- MITA Systems cooling stations: integrated water management to optimize consumption and reduce waste.

- MITA IoT remote management platform: real-time monitoring to optimize plant operation.

Examples of industry processes served by MITA Cooling Technologies

MITA has successfully contributed to several projects in the food industry, supporting specific processes. Following are some examples.

- Tomato concentration: cooling of water from barometric condensers using MCC closed-loop towers to preserve the quality of the liquid.

- Whey recovery: initial cooling of whey using heat exchangers to maintain product integrity.

- Production for artisan ice cream parlors: use of evaporative towers to ensure optimal temperatures in refrigeration circuits.

MITA cooling systems for the food industry

MCC Closed-Circuit Evaporative Cooling Tower

Some industries need to keep the chemical-physical characteristics of the process fluids unchanged: in these cases, MCC closed-circuit evaporative cooling tower joins the game. Possibility to work in free-cooling mode. MCC-EC version available with electronically controlled fans.

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

MDC-V V-Type Dry Cooler

Ease of installation, operation and maintenance–serving even large systems: this is the MDC-V V-shaped dry cooler. The peculiar design of the coils allows a larger heat exchange surface area than table-top dry cooler systems. All in an easily scalable solution.

MITA Systems Cooling Stations

Complete solutions specifically studied and designed for a more efficient and automatic management of evaporative cooling towers and coolers.

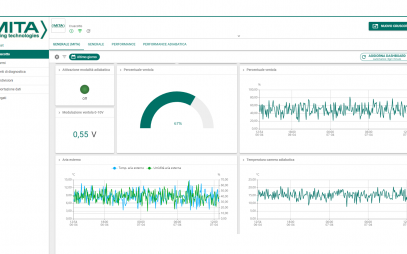

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA achievements for the food industry

Cooling Efficiency for a Food Company in Poland

MITA Cooling Technologies scores, together with the agency EETS, a new achievement for the food industry: a poultry products company chose the PAD-V adiabatic cooler for a section of its production processes.

Learn MoreCooling Technologies for a High-Quality Food Process

More than a hundred years ago it was an apple orchard: now it is one of the most important food industries in Sweden. This is the company to which MITA Cooling Technologies and CAMPreq have provided solutions-as manufacturer and process cooling consultant, respectively.

Learn MoreIndustrial Cooling Tower for Coca Cola in Kiev

A MITA cooling system serving one of the world's most celebrated multinational food & beverage companies: the Kiev-based Coca-Cola now uses a PME-E evaporative tower for its production facilities.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.