Installation Context: steel plants, foundry, aluminum production, steelcord production.

Cooling Technologies for Metalworking

Foundries, steel mills, aluminum production lines: the plant managers of these industries require operational continuity, significant thermal jumps in cooling and cost containment for management and maintenance. Remote management platforms are an ally.

Requirements: low resource use, remote control, high temperature ranges, easy maintenance.

Overview of Cooling Technologies: remote control systems, integrated management systems, cooling towers for industries (open circuit).

Cooling technologies for metal processing

Some examples can be given on the applicability of cooling technologies for metalworking (extremely heterogeneous scope).

- Let us start from metal heat treatments: here the cooling system is used to cool water coming from the heating furnaces of the pieces, as well as for cooling the water or tempering oil.

- In the sintered pieces production, the cooling technologies are used to cool the water coming from the hydraulic power packs of the presses and from the piece heating furnace.

- As for the hot metal stamping process, the purpose is instead to cool the water coming from the steel heating furnaces and from the air compressors of the presses, used to control the hammers.

- Finally, in the production process of die-cast parts, the industrial cooler is used to cool the water coming from the hydraulic power packs of the presses and from the molds.

MITA cooling systems for metalworking

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

PMM Modular Cooling Tower

This is a series of large industrial cooling towers for power generation, steel and aluminium processing, cogeneration and other large production sites. Efficiency, high performance, reduced installation and transport costs are granted.

Industrial Chillers

Output temperatures down to -20 ° and remote control as a standard: the industrial chillers proposed by MITA are suitable for all the industrial processes.

MITA Systems Cooling Stations

Complete solutions specifically studied and designed for a more efficient and automatic management of evaporative cooling towers and coolers.

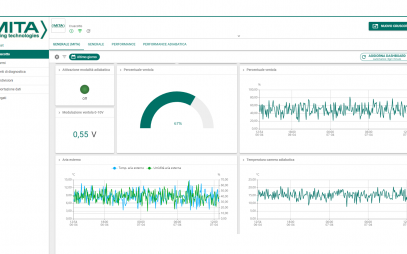

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA Projects

Fonderia Casati is Industry 4.0 also thanks to MITA Cooling Systems

Fonderia Casati, a historic company in Varese, has understood the importance of industrial process automation to maintain its competitiveness at the European level.

Learn MoreIndustrial Cooling Towers for a Steel Processing Plant in Sweden

MITA Cooling Technologies supplied two PMM open-loop towers for the Swedish multinational steel processing company SSAB: a few years later, we are receiving very positive feed-back regarding the technical solution and performance.

Learn MoreWater Cooling for Aluminum Production with Extrusion

A customer relationship cultivated over the years and a successful collaboration between MITA Group companies: over the years, MITA Cooling Technologies and MITA Water Technologies have provided Vedani Group with various cooling and process water treatment solutions, respectively.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.