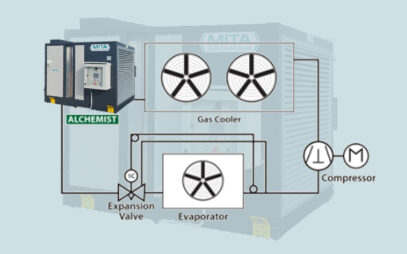

Installation Context: CO2 refrigeration units.

Cooling Technologies for Large-Scale Distribution and Supermarkets

Supermarkets and large-scale distribution are increasingly attentive to environmental sustainability: hence the choice to use natural refrigerants for chillers. In these cases, the adiabatic subcooler patented by MITA guarantees an extra step in efficiency: a solution that can be easily integrated into the system.

Requirements: continuity of operation, efficiency, performance increase, natural refrigerants.

Overview of Cooling Technologies: subcoolers for refrigeration.

Cooling technologies for large-scale retail and supermarkets: advantages

These are the advantages of cooling technologies for large-scale retail and supermarkets, such as subcoolers for refrigeration.

- High kWh savings in energy produced, compared to systems with gas cooler alone.

- Easy installation even in existing systems (retrofit).

- Compact design, modularity and easy maintenance.

- Software available to calculate ROI.

Alchemist combines adiabatic cooling with refrigerant subcooling in a way that increases plant efficiency. It is installed downstream of the condenser and/or gas cooler.

MITA Cooling Systems for Large-Scale Distribution and Supermarkets

Alchemist Adiabatic Sucooler

Performance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

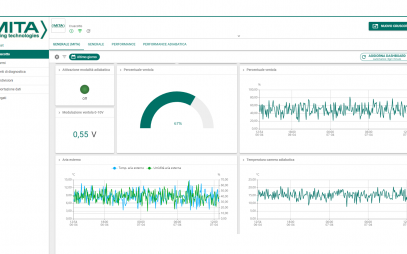

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA projects for Large-Scale Distribution and Supermarkets

Alchemist Subcooler for Efficiency in a Refrigeration Unit

A store in the province of Vicenza has achieved a significant improvement in the performance of a CO2 refrigeration system, with energy and cost savings: this is thanks to Alchemist, a plug-and-play subcooler that can be easily integrated into existing systems.

Learn MoreAdiabatic Subcoolers in Supermarkets in Northern Italy

Sustainability without loss of performance: this was the challenge of a large-scale retail player with many supermarkets in northern Italy to which MITA supplied several Alchemist adiabatic subcoolers.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.