Real Data: Efficiency Gains in CO2 Plants with Alchemist Subcooler

With this paper, MITA Cooling Technologies aims to share actual operating data from a transcritical cycle CO2 plant in which Alchemist has been included.

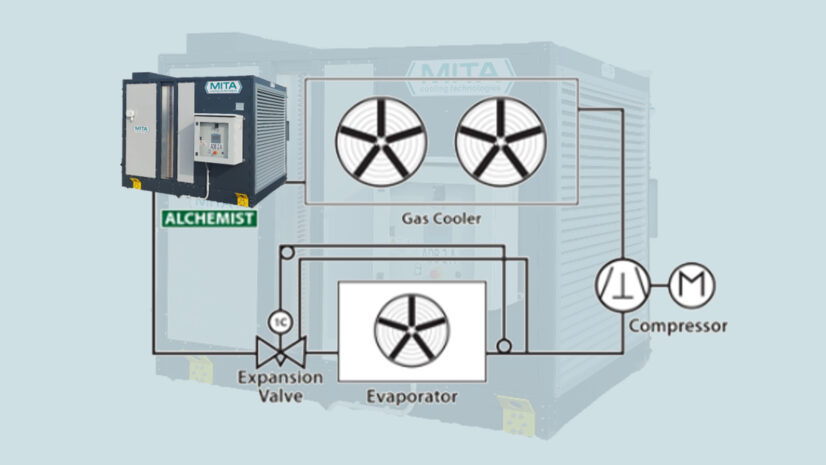

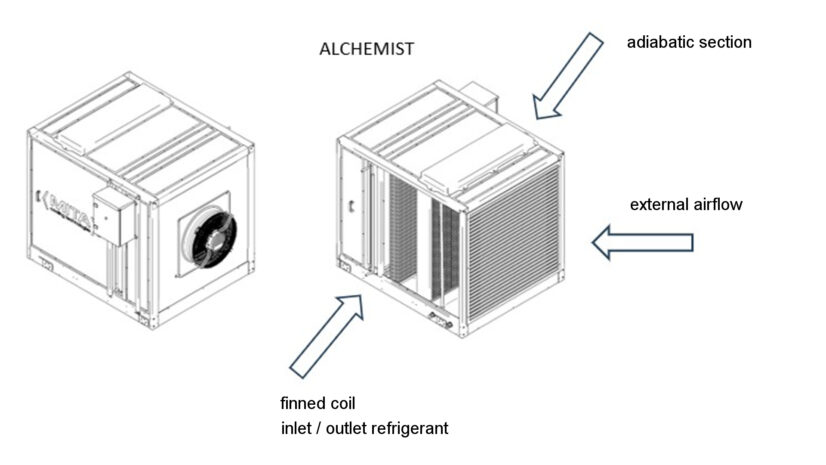

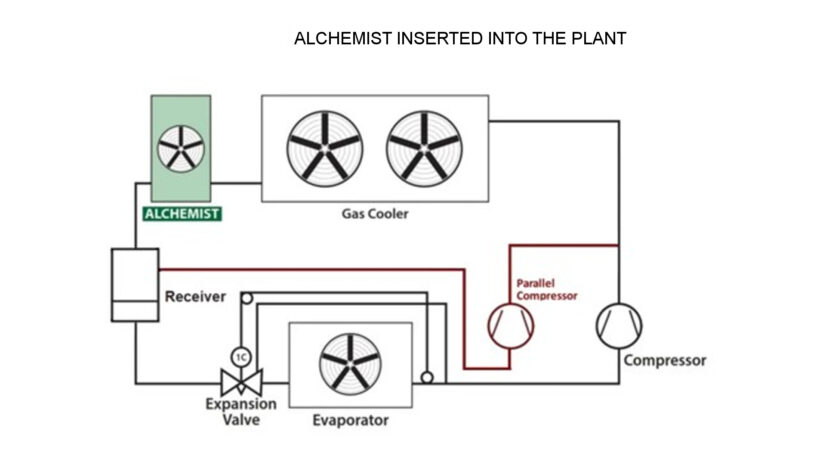

Alchemist is the adiabatic CO2 sub-cooler (MITA patent 17194148.7) designed and marketed by MITA, a product that easily fits downstream of the gas cooler in any transcritical CO2 system, typically in Commercial Refrigeration.

The case study aims to present the significant benefits brought by the patented Alchemist sub-cooler in terms of:

- reduction of energy use,

- reduction of circuit pressures.

Features of the plant

Place of installation (point of sale): province of Vicenza.

Maximum design power of the TN line of the point of sale: 164 kW.

Central refrigeration plant consisting of:

- no. 4 Dorin compressors, model CD 300 H, one of which is equipped with an inverter,

- no. 1 Dorin compressor, model CD 300 H, equipped with an inverter and used in parallel compression,

- no. 1 Alchemist model 4000 SR subcooler.

Collected Data

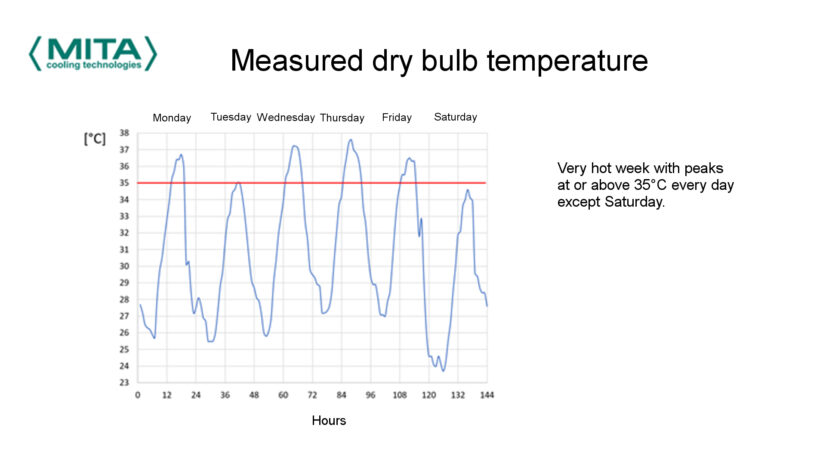

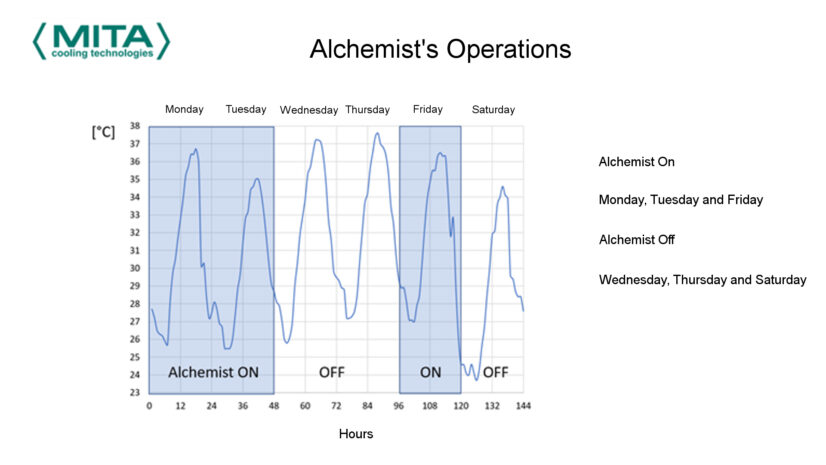

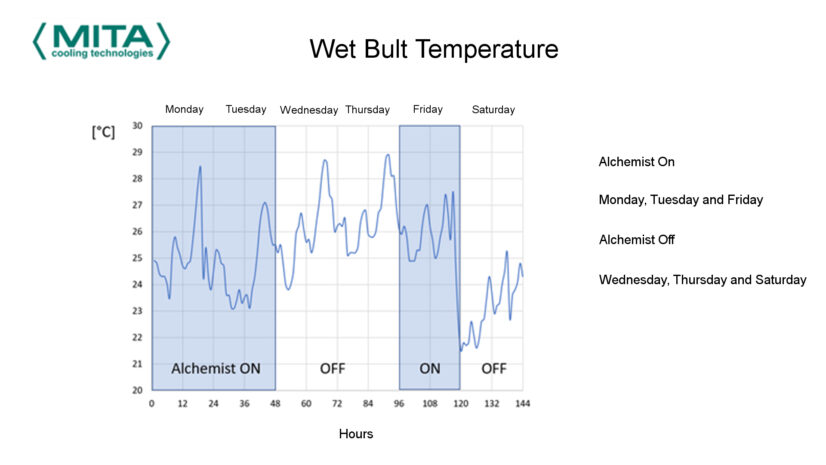

Taking advantage of the hottest season of the year, point-of-sale operation data was recorded in the summer of 2022, six days of testing with automatic detection instruments from 1 a.m. on Monday to midnight on Saturday.

Alchemist was automatically turned on and off to observe the differences between the following measured data:

- refrigerant outlet temperature,

- operating pressure,

- evaporation temperature,

- total electrical consumption of the refrigeration plant (including the fans of the gas-cooler and Alchemist),

- water consumption of Alchemist.

From these data were derived:

- the energy supplied by the system,

- the COP trend of the entire power plant, including the consumption of the gas cooler and Alchemist fans.

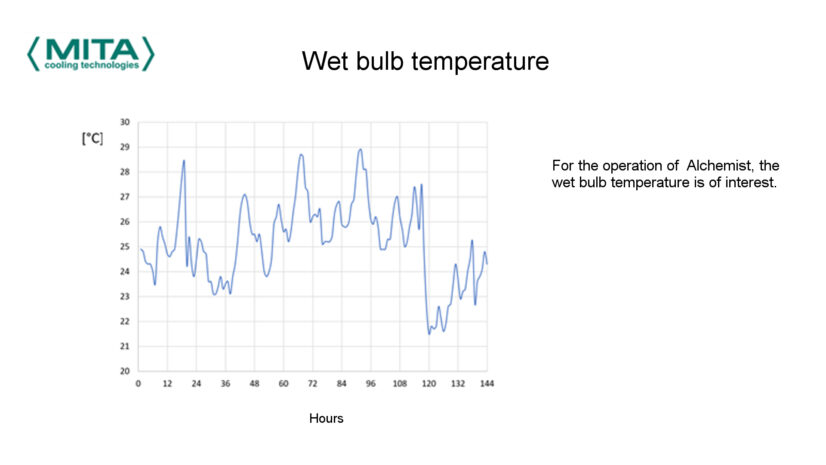

The week taken under analysis was very hot, with maximum temperature peaks of 35°C or more:

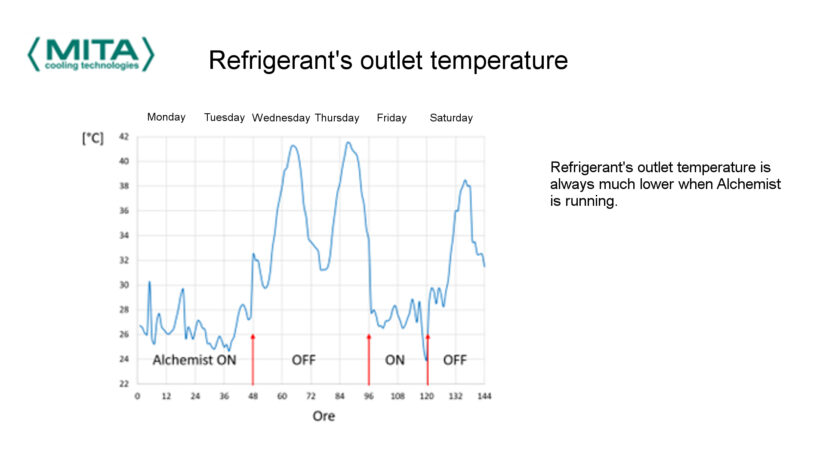

The operation of Alchemist brings the great advantage of lowering the refrigerant outlet temperature.

The diagram below clearly shows the sharp difference in the temperature of when Alchemist is running and when it is off.

Arrows highlight times when Alchemist is turned on and off.

At this stage, humidification was deliberately kept on at all times, precisely to better highlight the positive effects.

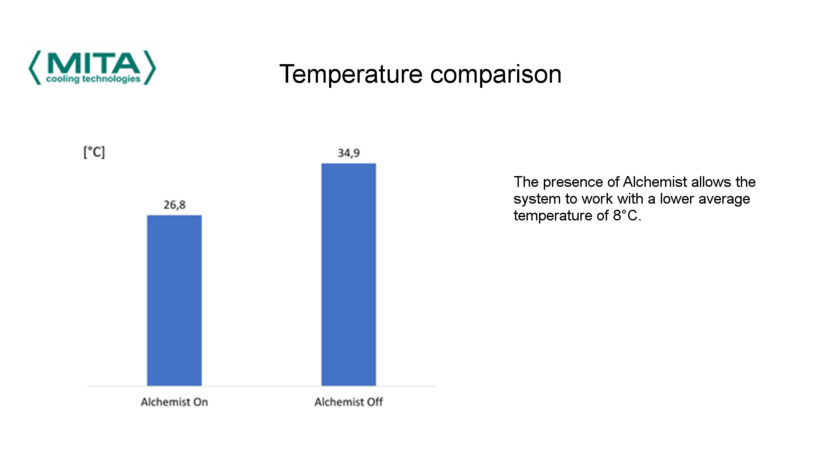

We proceeded to identify the average of the refrigerant outlet temperatures over the six test days, and then determined that Alchemist operation resulted in an 8°C drop in the refrigerant outlet temperature.

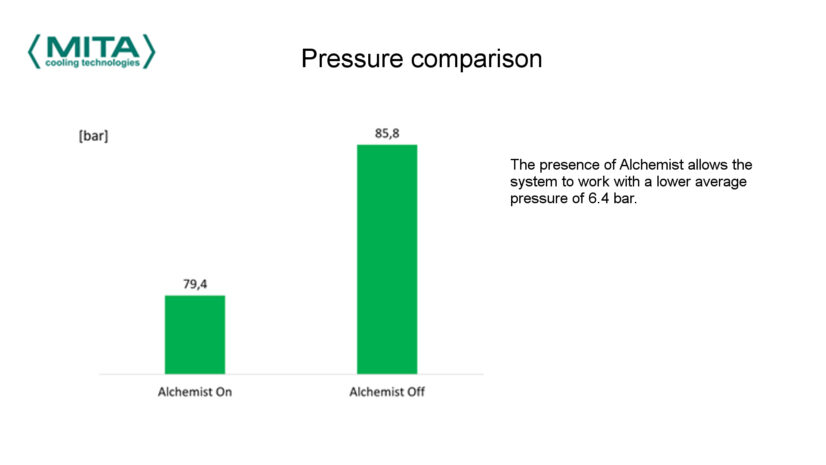

This scenario thus allows the “payoff effect” to increase, compressor consumption is lowered because working pressures are reduced:

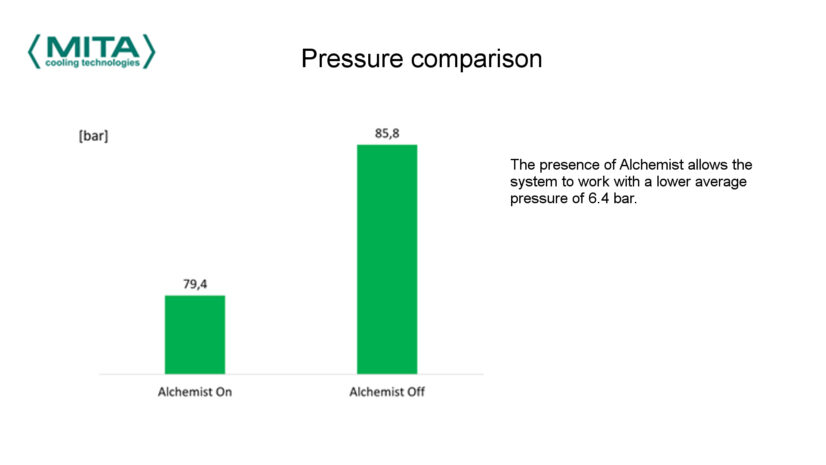

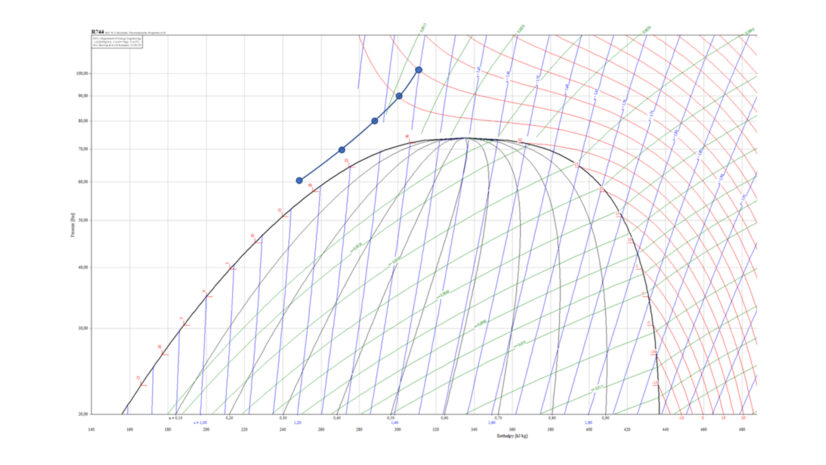

Pressure is adjusted according to the blue curve shown in the diagram below: each output temperature corresponds to an optimal pressure. The lower the temperature, the lower is also the pressure.

It can be seen that the working pressure is always markedly lower when Alchemist is running.

This condition allows the system to work in transcritical cycle almost all the time (above 73.5 bar), except for an extremely short period (end of the day on Friday), just before Alchemist is turned off.

The average “gain” during the week is about 6.4 bar, so an increase in system efficiency occurs.

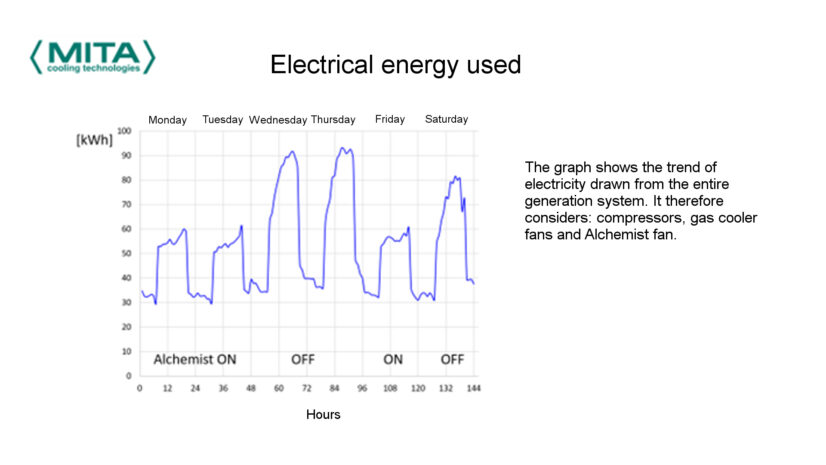

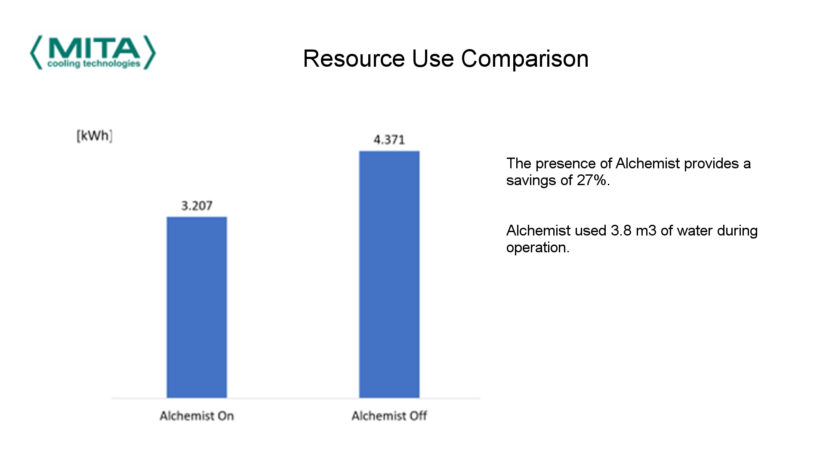

The most important aspect to dwell on is the overall power consumption, including the gas cooler fans and Alchemist.

The graph below highlights the sharp increase in consumption, attributable to the work of the compressors, when Alchemist is turned off.

In three days, the savings were more than 1,100 kWh, or about a 27%, with a water consumption of 3.8 m3.

It should be pointed out that the more correct saving figure, under normal conditions, might be around 22%, with a water consumption of about 3.2 m3 for the following reasons:

- the days of Wednesday and Thursday, when Alchemist was deactivated, were particularly warm compared to Monday and Tuesday,

- generally it might be useful to deactivate Alchemist with relative humidity above 75%.

Deduced data

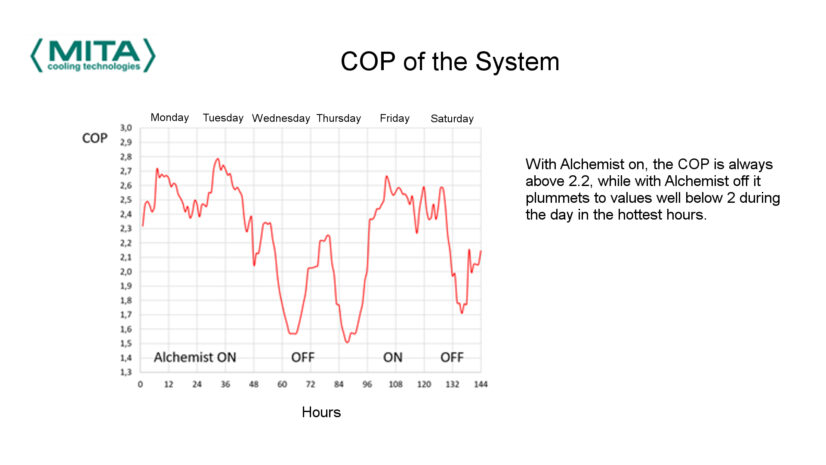

From the refrigerant outlet temperature and working pressure, also knowing the refrigerant evaporation pressure (another measured data point), through the polynomial formulas provided by Dorin it is also possible to derive the total energy delivered and the COP trend of the system:

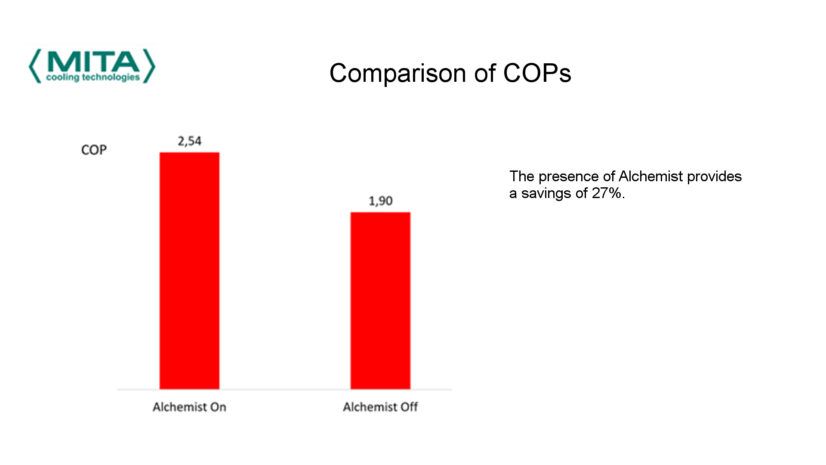

With Alchemist on, the COP is always above 2.2, while with Alchemist off, the COP plummets to values well below 2 during the day during the hottest hours:

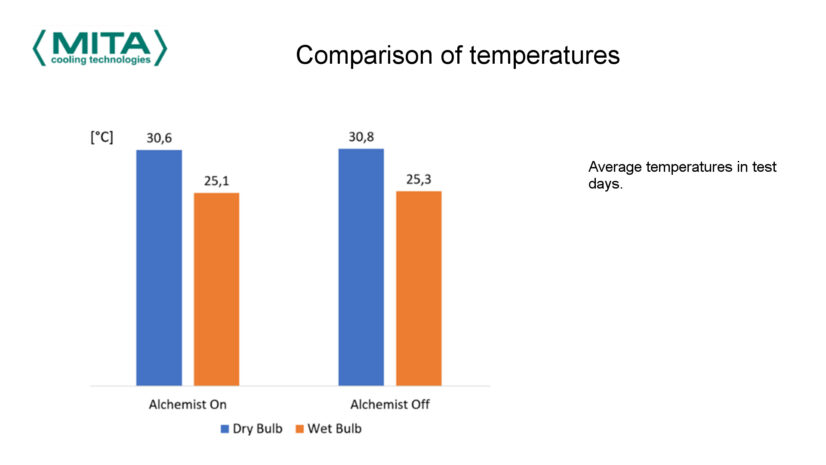

Alchemist on: average COP 2.54 (very high value, considering the average temperature of 30.6°C).

Alchemist off: average COP 1.90 (average temperature only two-tenths of a degree higher).

Conclusions

The test carried out in the particularly hot summer of 2022 shows how Alchemist enables significant reductions in electricity consumption, with extremely low water consumption.

Alchemist also reduces consumption during subcritical cycle operation, so its use is recommended in all CO2 systems, wherever they are installed.

Alchemist Subcooler for Efficiency in a Refrigeration Unit

A store in the province of Vicenza has achieved a significant improvement in the performance of a CO2 refrigeration system, with energy and cost savings: this is thanks to Alchemist, a plug-and-play subcooler that can be easily integrated into existing systems.

Learn MoreResources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.