How is the risk of Legionella managed in cooling towers?

Managing the risk of Legionella in cooling towers requires an integrated approach based on system assessment, proper positioning, water treatment, prevention, and continuous monitoring.

Several factors that promote the growth of Legionella must be considered:

Scaling and sediments, which consume disinfectant and create a protected environment for Legionella and other microorganisms.

Water temperature between 25°C and 45°C, a range in which Legionella proliferates; however, the bacteria can grow even outside this interval.

Water pH, which can affect the effectiveness of introduced biocides.

The presence of a bacterial load provides nourishment for Legionella, especially through the formation of biofilm. Biofilm shields Legionella from heat and disinfectants, offering both food and protection to microorganisms. It forms on any surface that remains constantly moist and can persist over time. Water stagnation promotes biofilm growth, leads to reduced disinfectant levels, and may create areas where the temperature of cold water increases. A cooling tower must therefore be well designed to improve system performance and operational safety.

The design should promote complete drainage, avoid stagnant zones, and allow easy access for maintenance. Corrosion-resistant materials and smooth surfaces limit biofilm adhesion, while high-efficiency drift eliminators reduce aerosol dispersion.

Regular cleaning and disinfection activities, along with preventive maintenance of basins, heat exchangers, and drift eliminators, form the core of an effective management plan. Routine monitoring through laboratory analysis and proper training of technical personnel ensure regulatory compliance and hygienic safety.

A correct water treatment program—combined with targeted design choices and consistent maintenance—keeps the system efficient and safe over time, preventing Legionella proliferation and ensuring high operational performance.

Learn more

Cooling Tower Water Treatment: what to know

Here a complete guide on how to establish an optimal cooling tower water treatment (systems and tricks). What is the aim of an automatic make-up system? Which is the role of a proper chemical treatment? How to maintain the circulating water at optimal operating limits? All questions your process cooling advisor can answer.

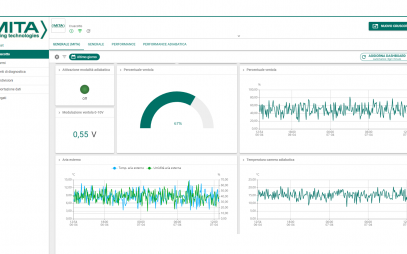

Water Control System in Evaporative Cooling Technologies

The so-called “water control system” is a particularly important topic in evaporative cooling circuits, both in industrial process and HVAC applications.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.