What role do selection software tools play in the design of cooling systems?

Selection software makes it possible to simulate thermal loads, climatic conditions, and design variables in order to determine the optimal configuration of cooling towers, dry coolers, or chillers. They provide comparative analyses of capacity, energy consumption, noise levels, and operating costs.

The goal is to ensure the right balance between performance, energy efficiency, and operating expenses.

These tools reduce design time and minimize the risk of errors, allowing designers to compare different technologies (such as adiabatic and evaporative systems), including from the perspective of resource usage, and to evaluate their behavior under real operating conditions. They automate the most complex calculations, improve dimensional accuracy of components, and immediately flag any incompatibilities or exceeded limits.

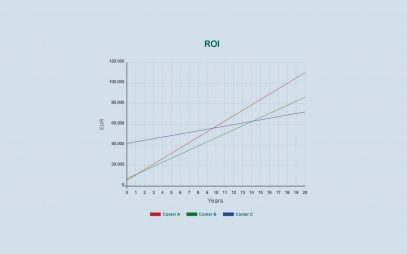

Key advantages include: precise component selection (such as compressors in chillers), energy optimization with life-cycle cost (LCC) analysis, and performance simulations that prevent oversizing. Selection and configuration software can also estimate economic indicators such as return on investment (per unit of time) and operating costs, providing both technical and decision-making support. Another benefit is the ability to generate technical reports, facilitating collaboration between designers, engineering teams, and sales engineers.

In summary, selection software integrates calculation, simulation, and analysis, making system design faster, more accurate, and more sustainable.

Learn more

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Industrial Plant Cooling: 12 + 1 Things to Consider before Looking for a Manufacturer

Is this the first time you have to deal with the cooling of your industrial plant? Or maybe do you wish to see a complete reference framework to carry out this task for your company? These guidelines will help you choose the best cooling technology for your plant's specific project needs.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.