Digitalization of cooling systems: how selection software, PLCs, and IoT improve system management

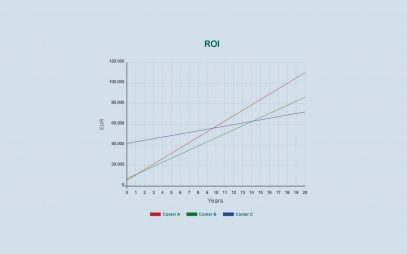

During the design phase, the use of selection and configuration software makes it possible to compare different solutions—chillers, cooling towers, adiabatic coolers, or dry coolers—by simulating their seasonal performance and heat loads. These digital tools also estimate energy and water consumption and help optimize system sizing.

During operation, PLCs (Programmable Logic Controllers) play a key role in system control: in cooling towers, they help optimize cooling cycles and ventilation, while in adiabatic coolers they automatically manage wetting cycles and operating modes (adiabatic or dry) based on climatic conditions.

In addition, IoT connectivity enables real-time remote monitoring of critical parameters, sending immediate alerts in the event of anomalies and allowing continuous data analysis for predictive maintenance. Thanks to IoT, technicians can monitor and intervene on the system remotely, enhancing responsiveness and reducing unexpected downtime.

Learn more

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Integrated Cooling Systems: which Advantages thanks to an Inverter

Lower motor power consumption, optimal process conditions and some other advantages delivered by an inverter system on cooling equipment.

Industrial Plant Cooling: 12 + 1 Things to Consider before Looking for a Manufacturer

Is this the first time you have to deal with the cooling of your industrial plant? Or maybe do you wish to see a complete reference framework to carry out this task for your company? These guidelines will help you choose the best cooling technology for your plant's specific project needs.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.