How can water use be reduced in evaporative and adiabatic cooling systems?

Modern evaporative coolers use automatic blowdown systems controlled by conductivity sensors, partial recovery of discharge water, and optimized make-up strategies. Adiabatic systems, on the other hand—with the proper use of sensors and PLC-based parameter settings—use water only during periods of maximum thermal load, reducing overall consumption compared to traditional cooling towers (though with some loss of efficiency). The adoption of recovery circuits also allows part of the water to be reused in any cooling system that relies on this resource.

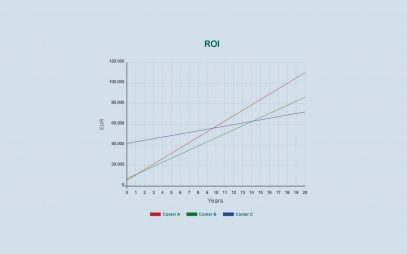

Configuration software used by some cooling-technology manufacturers selects systems based on water availability and cost in the installation area. The goal is to balance cost, cooling efficiency, and sustainability.

Learn more

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

Integrated Cooling Systems: which Advantages thanks to an Inverter

Lower motor power consumption, optimal process conditions and some other advantages delivered by an inverter system on cooling equipment.

Industrial Plant Cooling: 12 + 1 Things to Consider before Looking for a Manufacturer

Is this the first time you have to deal with the cooling of your industrial plant? Or maybe do you wish to see a complete reference framework to carry out this task for your company? These guidelines will help you choose the best cooling technology for your plant's specific project needs.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.