How can I achieve maximum energy efficiency from my industrial cooler?

Basically, it is possible to achieve maximum energy efficiency through a series of measures:

sizing a cooler according to the exact cooling needs, or slightly oversizing it to avoid operational issues during particularly hot seasons;

installing an intelligent control system to optimize operating parameters (a standard feature in some solutions such as adiabatic units);

performing periodic maintenance of the industrial cooler, following a precise schedule provided by the manufacturer.

More specifically, achieving maximum energy efficiency from an industrial cooler requires considering the entire system as a whole: design, control, and maintenance must work in synergy. Everything starts with proper system sizing, which must be calibrated according to actual cooling needs and capable of handling even the hottest seasons without difficulty. Added to this is the importance of intelligent control systems, capable of continuously optimizing operating parameters based on climatic conditions and thermal load. In many solutions, such as adiabatic systems, these controls are already built in and allow dynamic modulation of fan and pump activity, reducing consumption and waste.

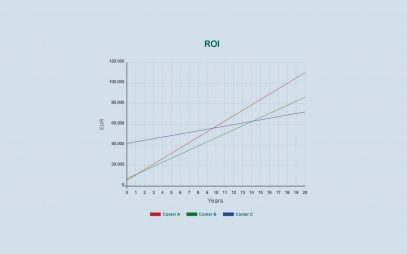

Energy efficiency, however, does not depend solely on control but also on the quality of the components used. Variable-speed EC fans and high-efficiency heat exchange sections contribute to improved performance while reducing energy demand. The adoption of modulation strategies—such as free cooling or adiabatic operation—makes it possible to take advantage of favorable environmental conditions to significantly reduce electrical consumption, with savings that can reach several tens of percentage points compared to traditional systems.

An essential role is also played by advanced PLC-based control systems, which integrate sensors, inverters, and predictive regulation algorithms to keep operating parameters constantly within the optimal range. These platforms monitor temperature, flow rate, and humidity, automatically adjusting the operation of the various components. Centralized supervision solutions also allow operators to analyze historical data and identify new opportunities for savings. Finally, the use of energy simulation software and artificial intelligence tools makes it possible to predict seasonal energy demand and optimize operating cycles, improving overall efficiency and reducing operating costs.

Supporting these activities, selection and configuration software is a valuable ally from the earliest stages of the project. It enables identification of the most suitable model, simulation of operating conditions, and precise calculation of expected performance, ensuring that the chosen cooler fully meets system requirements and maximizes long-term energy efficiency.

In summary, the key to success lies in a balanced combination of technology, intelligent control, digital tools, and periodic maintenance: only an integrated approach can ensure high performance, sustainability, and long-term operational continuity.

Learn more

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.

European Green Deal and Cooling

The EU Commission has set a goal of achieving climate parity in 2050: cooling technologies can contribute.

Integrated Cooling Systems: which Advantages thanks to an Inverter

Lower motor power consumption, optimal process conditions and some other advantages delivered by an inverter system on cooling equipment.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.