How does an adiabatic cooling system work?

Adiabatic cooling combines efficiency and sustainability. Outside air is pre-cooled as it passes through a dedicated section that is wetted (using cellulose pads or flocked PVC panels) before reaching the heat exchanger where the industrial fluid to be cooled flows. This “pre-cooling” process enhances heat transfer. Unlike a standard dry cooler, an adiabatic system uses water during summer peaks (and/or during the hottest hours of the day).

During the winter season and/or colder periods of the day, the adiabatic mode should remain deactivated, allowing the unit to operate entirely dry, with high efficiency and reduced maintenance. The adiabatic system should be designed to operate with short wetting cycles and equipped with precise control to minimize water consumption. The control of the adiabatic cooling mode — including wetting cycles and deactivation — should be managed automatically by a PLC with temperature sensors.

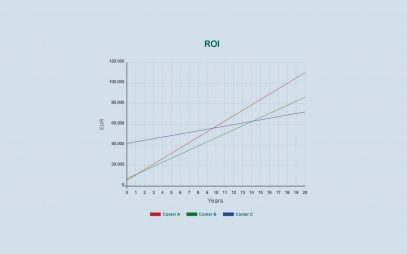

Adiabatic cooling can be particularly advantageous in temperate or warm climates and in locations where water availability and cost are critical factors. However, it is always advisable to compare the benefits of an adiabatic cooling system with alternative solutions, considering the installation area and using configuration and resource-optimization software (water and energy). The expected ROI is another key performance indicator to be assessed through comparative analysis.

Video of the operation of a cooler or adiabatic condenser.Learn more

Comparison between Cooling Tower and Adiabatic Cooler

Comparison of cooling tower (or evaporative tower) and adiabatic cooler: water and energy use, performance.

Adiabatic Cooling: one Eye on Efficiency, the Other on Reliability

Low operating temperatures and high COP, even in the hottest periods. A couple of reasons to consider an adiabatic cooling system.

Resource and Efficiency Optimization of Cooling Systems: How to Assess It

The comparison between different cooling technologies: a calculation software can now fulfill this task based on real climatic data.Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.