4. State-of-the-Art Components in MITA's Advanced Integrated Cooling Systems

Reliability, operational continuity, resource optimization: these are the advantages that MITA Cooling Technologies wants to offer its customers through integrated systems for cooling water management.

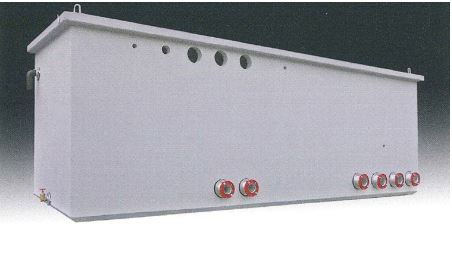

Each unit consists of a complete water treatment system, a pumping group with a hydraulic connection, an electrical command and control panel, a containment box (technical room), and a monolithic reinforced concrete water collection basin. It also includes essential electrical services such as automatic lighting, a service power outlet, and antifreeze protection via an electric heater.

Below are the systems that make up MITA System A and MITA System B.

Pumping. The system is equipped with a separate dual hydraulic circuit – a tower circuit and a user circuit – each managed by a dedicated pumping group for greater flexibility. Both circuits are managed by inverters, ensuring adaptability to the thermal load, significant energy savings, safe operation, and a reduced noise level. The pump is a standardized, monobloc centrifugal pump with direct motor-pump coupling, compliant with the EN 733 standard for reliability and interchangeability. It is equipped with an anti-vibration joint, a butterfly valve, and a check valve.

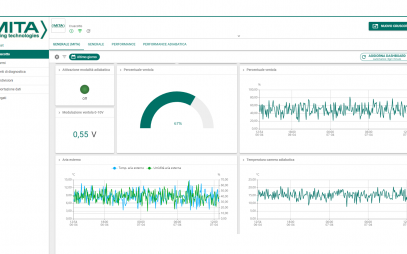

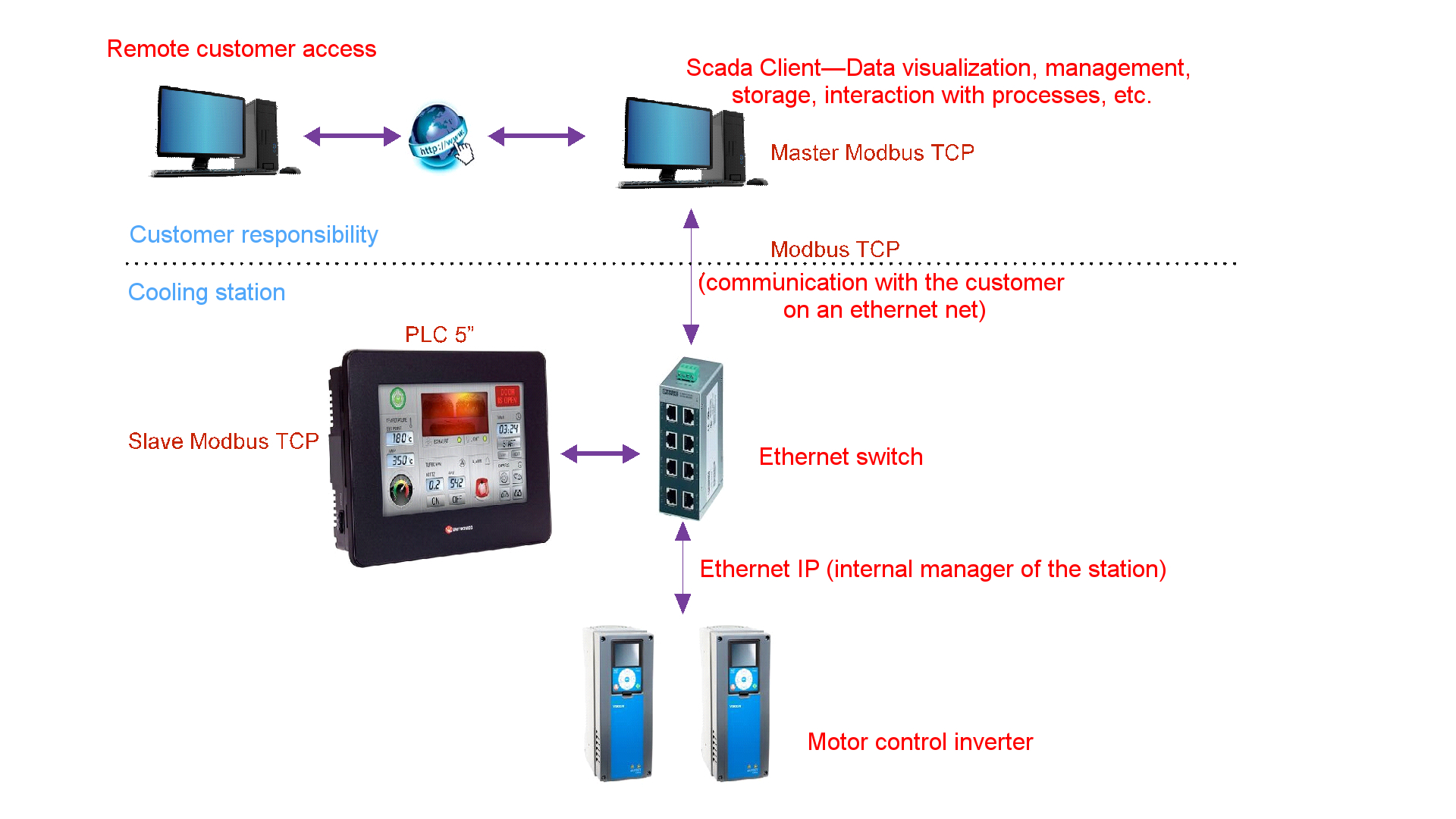

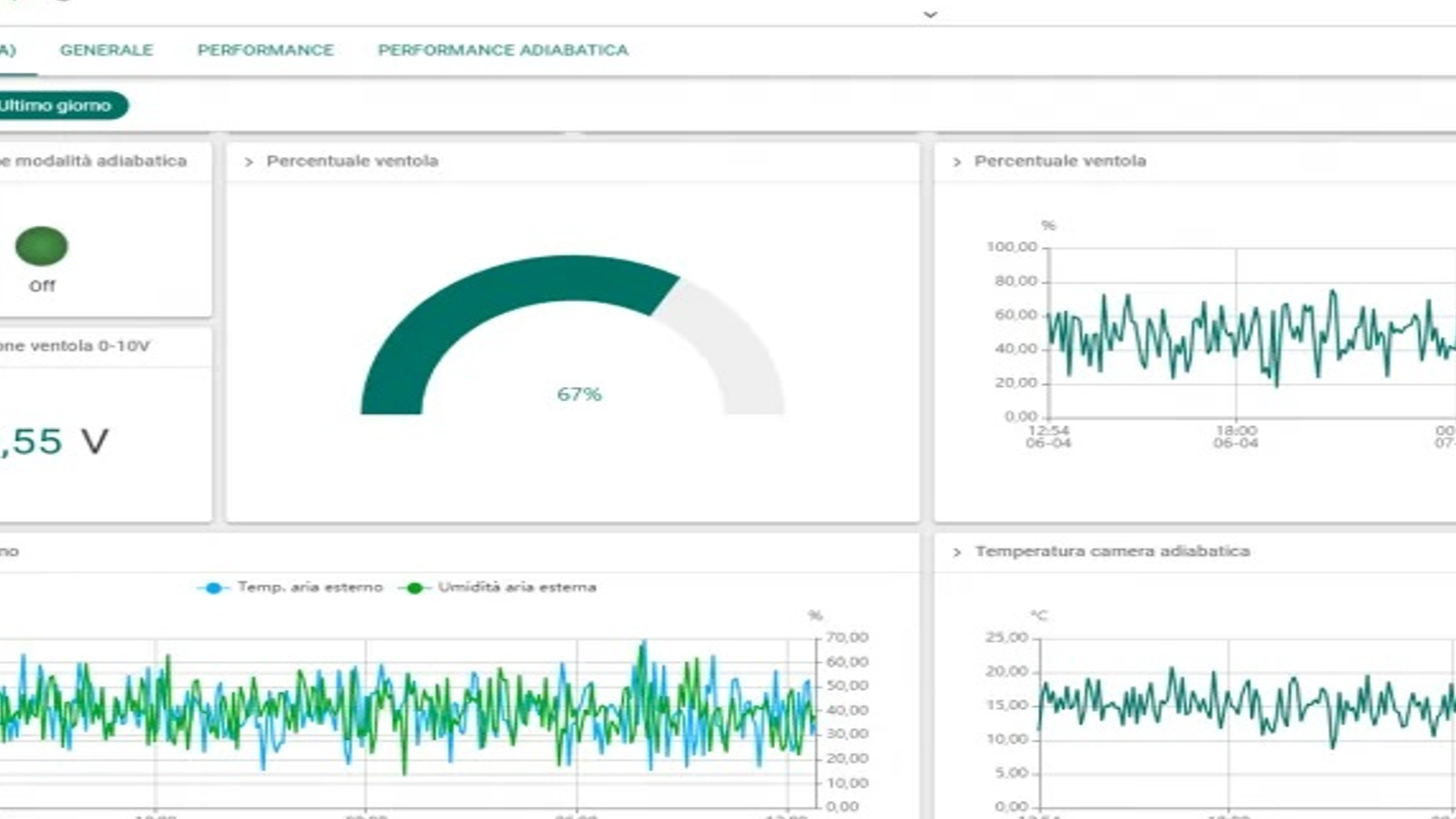

Intelligent control panel. The system management is entrusted to a sophisticated electrical command and power panel, designed for the automatic operation of the cooling circuit with an evaporative tower. A touch-screen PLC ensures maximum control security, a programmable function, and clear alarm signaling with a historical data log. Remote control functionality is also available via a start/stop command and a general alarm contact. The panel has IP54 protection.

Precision sensors. The unit is equipped with high-precision 4-20 mA sensors for temperature control and pressure control (316 stainless steel sensor for inverter regulation). The water level is monitored by a 4-20 mA sensor paired with a capacitive safety sensor to protect the pump from low water levels, with transparent piping for visual inspection.

Automated water treatment system. Fundamental for efficiency, water quality is managed by equipment designed to prevent scaling, corrosion, and organic contamination.

The DOSC (dosing and salinity control) provides proportional dosing of an anti-scaling, anti-corrosive, and biocide product based on actual water usage, with salinity controlled by automatic timed blowdown.

The SAL CONTROL offers precise salinity management via timed blowdown or an inductive/resistive conductivity meter.

The electronic water softener (CAB and VD), including the dual-column volumetric regeneration system, ensures a continuous supply of softened water by removing calcium and magnesium salts, reducing scaling and improving operational savings.

Water Treatment for Integrated Cooling Systems

Robust assembly and connectivity: all internal equipment is pre-connected hydraulically and electrically within the central unit. The piping uses black steel with submerged arc welding and a self-centering joint, or a galvanized threaded connection for smaller diameters, reinforced with an anti-vibration joint and secured to the structure. The electrical connection uses a double-insulated multi-polar cable with IP55 protection, compliant with the CEI-UNI standard.

Different systems, a single goal: to manage cooling water efficiently, safely, and automatically.

Cooling Tower Water Treatment: what to know

Read the article and know more