3. MITA Open Loop Evaporative Towers: How to Choose

MITA Cooling Technologies offers a wide selection of open circuit cooling towers, designed to meet a broad range of industrial and HVAC/R needs.

For applications requiring small and medium capacities, MITA offers factory-assembled units. The PMS Series is entirely made of lightweight, self-supporting fiberglass, ideal for corrosion resistance, and uses efficient axial fans for low-noise operation. The MCT Series, on the other hand, offers a compact monoblock design in fiberglass, particularly suitable for tight spaces or indoor installations. It is distinguished by the use of centrifugal fans, designed for air ducting and smaller spaces, with the MCT-EC models achieving extremely low noise levels thanks to electronically controlled “plug fans”.

For medium and large capacity needs, the PME-E Series and its extension PME-XL are robust towers, also factory-assembled. Their construction combines a solid hot-dip galvanized steel structure with fiberglass sandwich panels, offering mechanical strength and good acoustic insulation. They use high-performance axial fans and are designed for easy internal access, which simplifies inspection and maintenance operations.

For large industrial plants and large-scale applications, MITA provides high-capacity solutions often assembled directly on site. The PMM Series is characterized by a modular design, with factory-pre-assembled components to facilitate transport (including via container) and rapid on-site installation. It incorporates fiberglass panels and a steel structure, with axial fans equipped with a mechanical gear reducer for optimal performance and contained noise levels. For the largest plants and the most demanding environments, the PU Series (designed by TORRAVAL Cooling) is field-erected, offering structural versatility in concrete, steel, or pultruded GRP profiles to withstand extreme conditions such as seismic loads, wind, and snow. These towers also use axial fans with gear reducers to maximize energy efficiency.

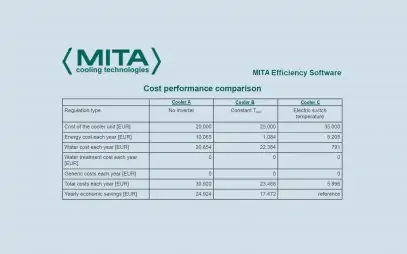

Across the entire range, MITA emphasizes resource optimization and advanced control. The MITA Control System (MCS), with VSD (inverter) support, dynamically modulates thermal performance, significantly reducing energy and water usage, mechanical wear, and noise. This system also enables Industry 4.0 functionalities, allowing for remote monitoring and data collection. MITA’s consultative approach, supported by advanced simulation software, guides customers in choosing the most suitable solution, balancing initial investment with long-term operating costs and sustainability goals, also offering options for refurbished units for a circular economy.

Ask for Information