Minumum resourse use. Short wetting cycles during the hottest seasons, controlled fan speed.

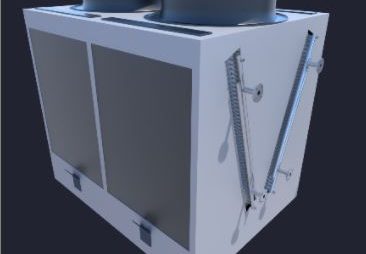

PAD-XL R Adiabatic Condenser

for condensing refrigerants (Ammonia NH3)Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

Automatic operations. Intelligent regulation of fans and dampening cycles.

Compact and integrable design. Simple and easily integrated into existing systems.

Effficiency and optimal resourse use. MITA solutions are selected through advanced software in order to fit the plant characteristics.

Quick pay-back. Pre-selection performed together with the client, based on their project requirement.

Industry 4.0. Possibility of control, monitoring and data collection on company management system.

How it works

The PAD-XL R adiabatic condenser follows the same principle as the PAD-XL W adiabatic dry cooler for liquids: dry operation in cold weather, adiabatic operation in warm weather (“adiabatic pre-cooling”).

The PAD-XL R machine type is sometimes referred to as “dry condenser with adiabatic pre-coolers” or more rarely as “air-cooled condenser with adiabatic pre-coolers”.

MITA Patent 2 206 980 B1.

Ask for a Quote

BIM Files

Download PAD on Skeinforce

VDI Hygiene Certification

Download the document issued by NeridionTechnical Features

- Models completely preassembled and equipped with an electrical panel (PLC that allows continuous optimization).

- Humidifier pack with high water retention capacity in flocked PVC (very short wetting cycles).

- Adiabatic circuit, protected inside, designed to recover water without requiring treatment.

- Double V coils. EC fans for low electrical use and noise.

- Support carpentry made of press-folded galvanized sheet metal and subsequently protected by an epoxy paint cycle.

- Each machine can be equipped with accesses for inspections and maintenance of internal parts.

- No risk of Legionella and aerosol.

Environmental and economic sustainability of PAD-XL R adiabatic condenser

- Minimal use of water (only for adiabatic operation), useful for facilitating heat transfer (i.e., cooling of the process fluid).

- Optimized energy use (higher efficiency due to adiabatic supply).

- Smaller installation spaces compared to the 100% air solution.

- Falls within the product categories that MITA is able to regenerate.

- Indication of “carbon footprint” from the MITA team.

Evaporative and Adiabatic Condenser for a Dairy in the Langhe Region

Langhe, a historic area of Piedmont known for its wines and haute cuisine. MITA Cooling Technologies participated in the modernization of a dairy's refrigeration system with two heterogeneous solutions: the MCE evaporative condenser and an adiabatic condenser.

Learn MoreTools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Your Plant Needs

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.