Research & Development

The cooling technologies of tomorrowInnovative solutions, research for new materials, performance tests: we try to offer you cutting-edge cooling technologies and we do it thanks to major investments in the R&D Department. Nonetheless, we have the aim of always remaining reliable.

R&D Department

MITA Cooling Technologies is at your side to guide and support you in choosing the most efficient industrial cooling solution: we have a wide range of reliable and technologically innovative solutions.

For this reason, the company continues to invest significant economic resources, time and energy researching and developing cutting-edge solutions and materials. They are tested with certified instrumentation. We make use of the collaboration of important exponents of the national academic world and international partners.

All our activities are also carried out with a view to eco-sustainability, in line with the goals subscribed to in the 2030 Agenda for Sustainable Development.

Tell us Your Needs

Some of our R&D activities

To be your cooling advisors, you need a full range of solutions. This is why we invest time and energy in product innovation, by attending international technical tables and also collaborating with one of the most prestigious Italian polytechnic universities.

Do you want to know some of our Research and Development activities?

Research new materials, with particular attention to sustainability and certifications required by the market.

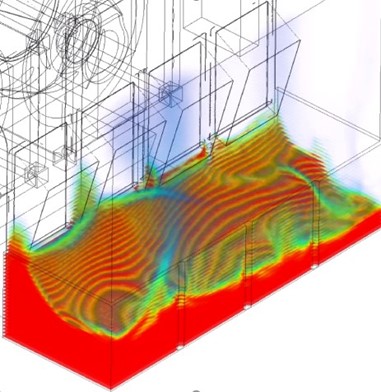

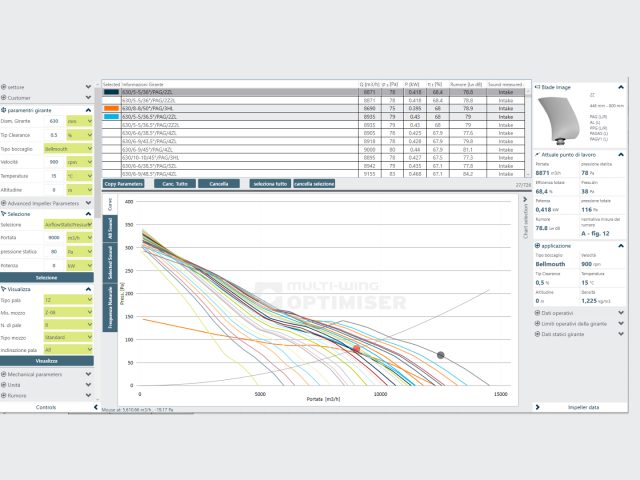

Study and implementation of new cooling technologies and new construction solutions.

Performance testing and analysis.

The stages of our evolution

Since 1960, our evolution continues to serve customer needs. Some recent projects.

2017

- Restyling of the PAD-V adiabatic dry coolers.

- Alchemist patented CO2 subcooler.

2018

- MCC-T (large closed circuit towers).

- Industry 4.0 software: MITA IoT.

2019

- “Super Silent” evaporative towers PME-E SPL.

- Advanced configuration and resource use analysis softwares: MITA Project and MITA Efficiency.

2020

- Expansion of the range of PAD-V adiabatic dry coolers.

- BIM drawings.

- Sound-level calculator software.

Our 2030 Agenda

- Optimized efficiency, reduced resources and ease of use. Always.

Last News

MITA at Chillventa 2024

The international rendezvous with industrial refrigeration is renewed again this year: MITA Cooling Technologies will participate in Chillventa 2024. “Chillventa

MITA at Mostra Convegno Expocomfort 2024

Also for this edition, MITA Cooling Technologies will not miss the appointment with the HVAC+R world: in fact, we will

MITA at Refrigera 2023 Bologna

MITA Cooling Technologies has taken part in Refrigera 2023, the international exhibition dedicated to the entire industrial, commercial and logistics

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesTools to help you choose

Preliminary plant evaluation

Tailor-made design

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.