Un sistema di raffreddamento adiabatico (dry cooler adiabatico per liquidi, condensatore adiabatico per gas) è un sistema che combina il principio di un dry cooler (raffreddatore a secco) con il pre-raffreddamento adiabatico dell’aria esterna.

Read all FaqAdiabatic Cooling Systems

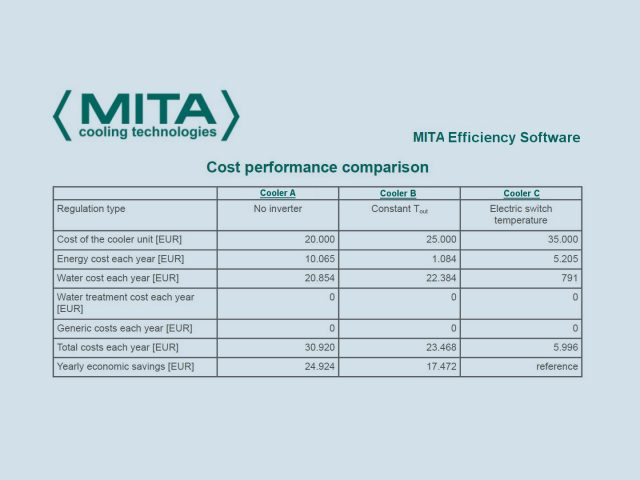

Extraordinary water and energy savings, optimized performance: adiabatic coolers and condensers are increasingly appreciated by engineers and production managers who seek the right balance between the advantages of the dry and evaporative systems.

Requirement: to save water and energy

Operating complex plants with ever-decreasing resources means that it is natural to pay attention to water and energy consumption. A need that cooling technologies have long since remedied.

Tell us Your Needs

Solution: adiabatic coolers and condensers

The adiabatic industrial liquid cooler and the adiabatic gas condenser are the natural solution to optimise performance and save resources at the same time:

- adjustable fan rotation speed,

- modulation of wetting cycles

- and flexible operation change from dry to adiabatic are managed by a PLC.

Some technological solutions, such as humidifier packs made of highly absorbent materials, further reduce water consumption.

Adiabatic Cooling System: What to KnowExpected life cycle and return on investment

Among the commercially available cooling systems, the industrial adiabatic cooler (or “dry cooler with adiabatic pre-coolers”) is one of those with the longest expected life cycle, especially if designed with certain features. Quick pay-back is also guaranteed by low water and energy consumption. Always bearing in mind, of course, any technical limitations that a cooling consultant may have to face: process temperature or installation space.

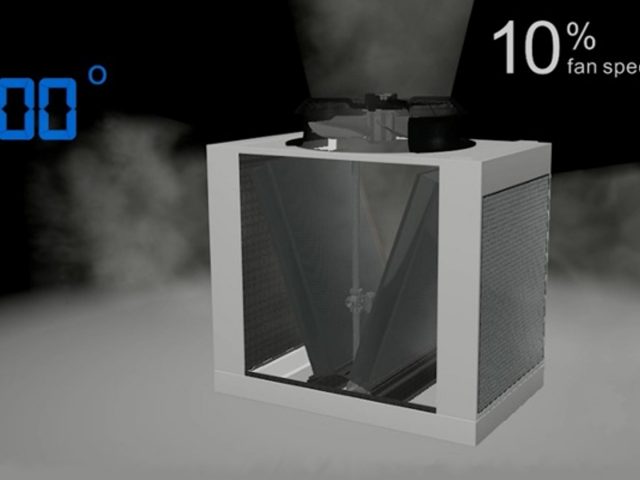

Adiabatic operation in hot periods...

- The external air passes through the humidifier pack.

- The adiabatically cooled air is conveyed to the finned coils: the efficiency increases.

- Capable of working at lower ambient temperatures.

- No direct contact between water and finned coils.

... Dry operation in cold weather

- The external air is aspirated and conveyed directly to the coils.

- Humidification is deactivated: no water in the circuit.

- Fan speed modulated according to temperature.

- Guaranteed water and energy savings.

FAQ: Adiabatic Cooling

Evaporative and adiabatic cooling both take advantage of air to lower the temperature of a process fluid (water, water and glycol, gas).

Read all FaqBoth systems use water, but in different amounts, in different ways, and with different levels of efficiency. The direct evaporative

Read all FaqThe structure and components of the two systems are, of course, a consequence of the two different operating principles.

Read all FaqAdiabatic cooling systems (adiabatic dry coolers for liquids, adiabatic condensers for gases) are the optimal solution where the goal is to save water, either due to the absence of that resource or to risks associated with its management.

Read all FaqSome main advantages can be enumerated, related to reduced water use and optimized operation during different seasons and times of the day.

Read all FaqDo you wish to have free advice?

Contact Us NowMITA Cooling Solutions

-

for medium and large plants

for medium and large plantsPAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

-

for condensing refrigerants (Ammonia NH3)

for condensing refrigerants (Ammonia NH3)PAD-XL R Adiabatic Condenser

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

-

to subcool R744 in transcritical plants

to subcool R744 in transcritical plantsAlchemist Adiabatic Sucooler

Performance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

Some MITA Projects

PAD Adiabatic Coolers for Ansaldo Energia (Utilities)

One of the most advanced poles for the study of power grids in Europe, in Sardinia, also bears the signature of MITA Cooling Technologies: this is thanks to 13 adiabatic coolers supplied to Ansaldo, among the main implementers of the work.

Learn MoreExtraordinary water savings for the plastics industry with the MITA adiabatic system

A plastics processing company in the province of Lecco has chosen the PAD-V cooler for the cooling circuit of its production plant: the eco-sustainable system that cuts water and energy bills.

Learn MoreAdiabatic Subcoolers in Supermarkets in Northern Italy

Sustainability without loss of performance: this was the challenge of a large-scale retail player with many supermarkets in northern Italy to which MITA supplied several Alchemist adiabatic subcoolers.

Learn MoreSee More Technologies

Newsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.