Process examples: food storage, cold chain for logistics.

Cooling Systems for Industrial Refrigeration

Industrial refrigeration is critical to maintaining the cold chain in industries such as food and logistics. MITA Cooling Technologies offers refrigeration systems, and chiller-condensers to support them, that maximize energy and water efficiency, ensuring operational continuity and adaptability to different refrigerant gases. From evaporative towers to evaporative condensers and chillers with free cooling, MITA meets all industry needs with advanced technologies and IoT management platforms.

Typical needs: energy efficiency, business continuity, management of various refrigerants, water conservation.efficiency.

Technologies offered: evaporative cooling towers, evaporative condensers, adiabatic coolers/condensers/subcoolers, Frigofluid chillers, IoT management.

1. Typical industry needs.

Companies involved in industrial refrigeration-such as food warehouses, logistics, and food & beverage production-need solutions that ensure high efficiency and low energy and water consumption.

Business continuity is essential to avoid interruption of the cold chain, as is flexibility in handling various refrigerants, including ammonia (NH3) and environmentally friendly refrigerants (e.g., CO2). These needs require reliable, efficient, and easy-to-monitor refrigeration and cooling systems that are ideal for optimizing resources in storage and production processes.

Tell us your cooling needs

2. MITA Cooling Technologies' Solutions for the Industry

MITA Cooling Technologies supports industrial refrigeration with tailor-made solutions designed to meet efficiency and reliability requirements.

- MCE evaporative condenser: also suitable for ammonia refrigerant applications, provides high condensing efficiency for various types of industrial chillers attached to refrigeration processes.

- PAD-XL R adiabatic condenser: ideal for water-efficient settings. It reduces water consumption and offers stable performance.

- PME-E evaporative cooling tower for chillers: it optimizes the energy output of chillers, reducing operating costs and the electrical power required for cooling.

- Alchemist adiabatic subcooler: plug-play solution easily integrated to existing refrigeration systems (CO2 or fluorinated refrigerants) to increase efficiency.

- Frigofluid chillers with Free Cooling or with environmentally friendly refrigerants: allow to reduce energy consumption, taking advantage of natural cooling when weather conditions allow, and reduce environmental impact without loss of performance.

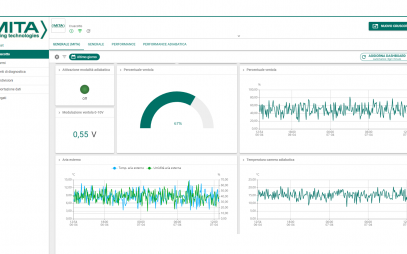

- MITA IoT: remote management platform that enables real-time monitoring and optimization of plant operation, improving efficiency and predictive maintenance.

MITA Cooling Technologies is committed to offering industrial refrigeration solutions that meet sustainability and resource-saving criteria.

3. Examples of Processes Served

MITA technologies are used in numerous processes in industrial refrigeration, such as:

- food storage: to preserve fresh products (dairy, meat, fruits and vegetables) without interruptions in the cold chain;

- logistics plants: refrigeration of environments to maintain optimal temperatures for food products destined for distribution;

- food & beverage production lines: cooling of refrigeration units used in production processes to ensure consistent product quality.

4. Focus: cooling of refrigeration units

A typical application of the evaporation or adiabatic technologies is the cooling of refrigeration units (or chillers), with water tower condensation.

The use of these systems is often preferred, rather than an air condenser for a technical reason linked to the better output of the refrigeration unit and the cooling unit’s lower electric power installed. With the use of the tower, however, it is necessary to provide an appropriate treatment system for the make-up water, which is not necessary for air condensers.

Ask for informationMITA Cooling Systems for Industrial Refrigeration

MCE Evaporative Condenser

Compact, efficient and easily accessible: MCE evaporative condenser ensures refrigeration operators all the operating standards of its own technology class. The typical MITA evaporative coolers’ durability over time is a plus. MCE-EC version available with electronically controlled fans.

PAD-XL R Adiabatic Condenser

Ideal for water saving maintaining a high efficiency. All operations are managed by PLC with the possibility of remote management in “Industry 4.0” mode. Both HVAC and refrigeration sectors can be served.

PME-E Open-Circuit Evaporative Cooling Tower

A light and non-corrodible open-circuit evaporative cooling tower: process industry and HVAC operators will be able to count on its multiple versions and ease of transport and installation.

Alchemist Adiabatic Sucooler

Performance, savings and environmental sustainability thanks to a patented Plug & Play subcooler for refrigeration systems working with R744 (CO2) and fluorinated refrigerants (HCFC, HFC, HFO).

PAD-XL W Adiabatic Cooler

Ideal for those who want to use very little cooling water while eliminating its management, or as an alternative to the classic dry cooler, especially with performance in the hottest times of the year in mind.

MITA IoT Platform 4.0

Your cooler is transformed into a connected cooler “industry 4.0”: performance, resourse use, maintenance just a click away.

Some MITA Projects for Industrial Refrigeration

Ammonia Condensation for Refrigeration Units in Greece

MCE-model evaporative condensers are an efficient solution for condensing ammonia in refrigeration: a Greek plant engineer, who again supplied this MITA solution to one of his customers, partly due to Ecoref's support during installation, knows this.

Learn MoreEvaporative and Adiabatic Condenser for a Dairy in the Langhe Region

Langhe, a historic area of Piedmont known for its wines and haute cuisine. MITA Cooling Technologies participated in the modernization of a dairy's refrigeration system with two heterogeneous solutions: the MCE evaporative condenser and an adiabatic condenser.

Learn MoreEvaporative Condensers for a Brewery in Cuba

A Cuban brewery, during 2015, needed to replace the ammonia (NH3) condensing system from the compressors of the refrigeration units: MITA Cooling Technologies was involved in the supply of evaporative condensers.

Learn MoreYour Plant Needs

Tools to help you choose

Cooling Advisors

Preliminary plant evaluation

Tailor-made design

Resources

Best practices

Read all Pieces of Advice by MITA Cooling TechnologiesWhat to Know

Find Out All Technical TermsTechnical Articles

Read All our Technical ArticlesNewsletter

Subscribe to MITA newsletter and stay updated on technical solutions for industrial and civil cooling and get to know our offer.