Ammonia Condensation for Refrigeration Units in Greece

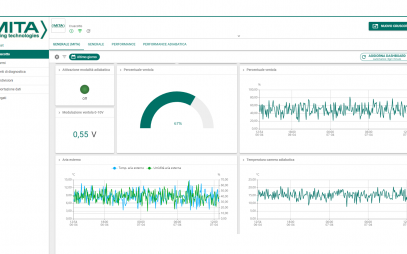

MCE-model evaporative condensers are an efficient solution for condensing ammonia in refrigeration: a Greek plant engineer, who again supplied this MITA solution to one of his customers, partly due to Ecoref's support during installation, knows this.

Learn More