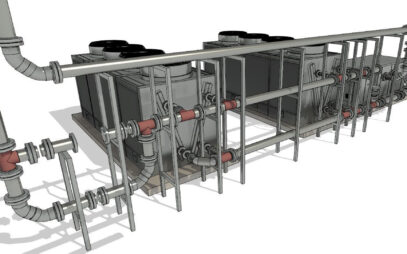

Dry Coolers and Chillers for Foundry in New Zealand

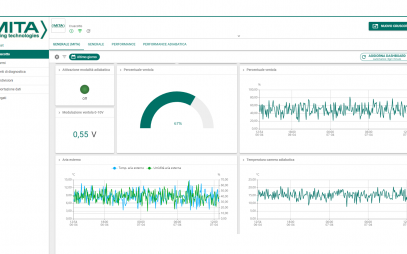

An industrial equipment integrator with more than 40 years of experience needed to cool resin sand molds for a foundry in New Zealand. MITA Cooling Technologies provided the solution: a combined dry cooler and chiller system ensured high performance even in a high temperature environment. The result of this integration? Reliable, energy-optimized cooling.

Learn More